The equipment and controls available to help with UK 2050 Net Zero Emissions goals

Climalife UK

Georgie Hillier, Sales and Marketing Coordinator

Georgie Hillier, Sales and Marketing Coordinator

By 2030 the current F-Gas Legislation effective in the UK requires the TCO2e of refrigerant being placed on the market to be reduced by 79% from the baseline figure which came into force in 2015

The overall aim is to reduce and contain refrigerant emissions by taking every step to adopt responsible refrigeration practices.

In addition to industry specific legislation, the UK government is looking for net zero carbon emissions by 2050 and managing refrigerant usage, minimising leaks and ensuring systems are as energy efficient as possible are all key aspects to the industry playing its part to achieve this target.

Whilst refrigeration and HVAC equipment choices will have a large impact on the ability to meet these goals, the choice of ancillary equipment and controls that are used alongside the system will also have their part to play.

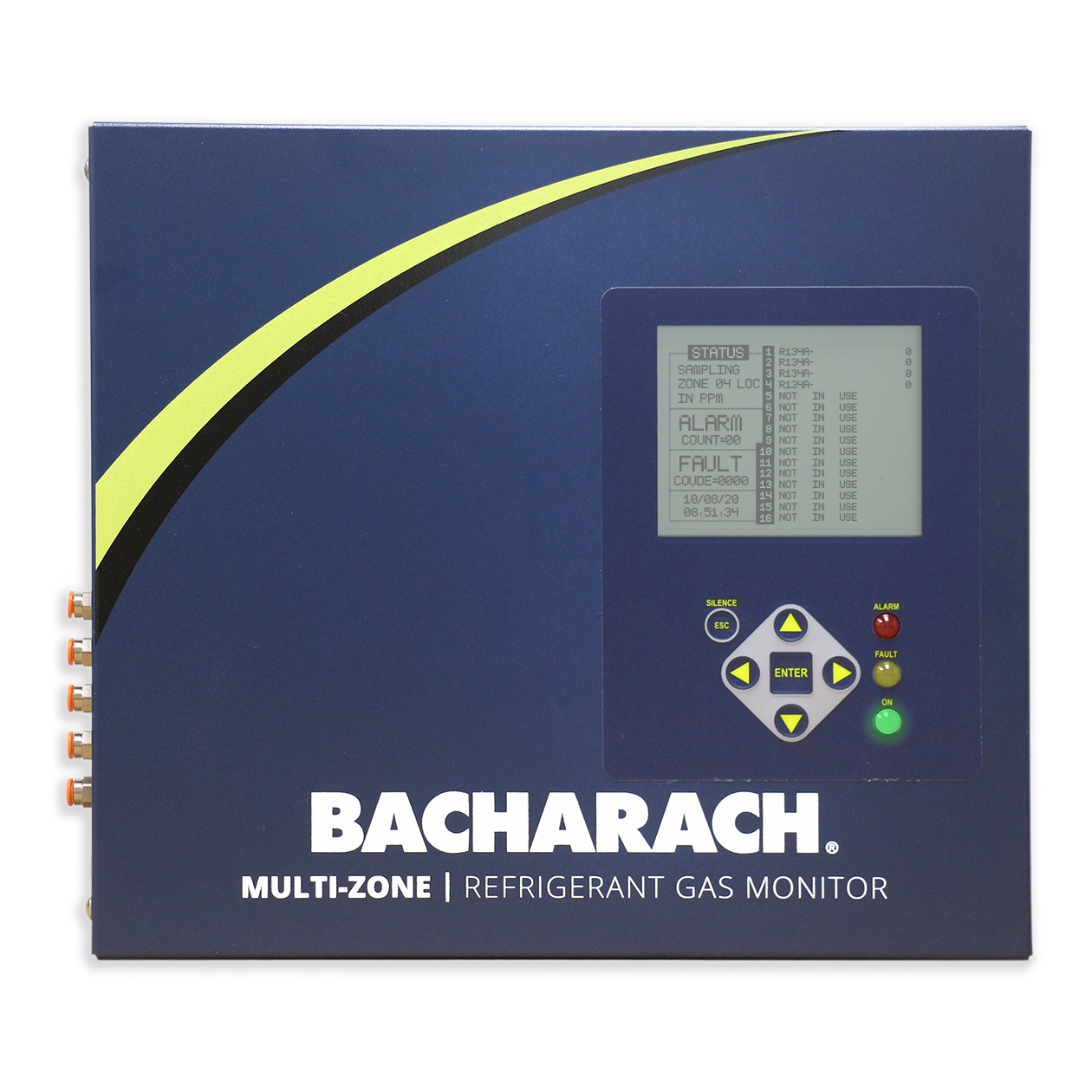

Leak Detection: Bacharach

A leaking system costs money and will go on costing money until the leak is fixed. Not only do fixed leak detectors ensure a leak is identified quickly they also help the equipment owner remain legally compliant with F-Gas legislation. It is mandatory under the F-Gas regulation (EU517/2014), for systems with a refrigerant charge of 500 TCO2e or more to be equipped with fixed leak detectors. F-Gas compliance also requires regular refrigerant leak checks and immediate repairs should any leaks be found.

Leak detection and prompt action following a leak being detected, can help to maintain the optimum efficiency of a system; avoiding an increase in energy consumption. Prompt action also reduces the amount of refrigerant lost to the environment and the amount needed for topping up a system to the correct level.

Leak detection: The solutions available

Climalife is a distributor of Bacharach products and provides a number of refrigerant monitoring solutions for F-Gas compliance such as the Multi-Zone and Single-Zone fixed refrigerant monitors and the PGM-IR portable refrigerant monitor.

Electric Controls: CAREL

As a Carel distributor, Climalife is seeing ever increasing demand for Electronic Expansion Valves (EEVs) due to their diverse use in the marketplace. From use in brand new systems to use in the refrigerant conversion of existing systems, the Carel products are an ideal option for many businesses as they look to move to low GWP refrigerants.

EEV’s act to control the flow of refrigerant into an evaporator. They do this by responding to signals sent by an electronic controller which in turn controls a small motor which is then used in order to open and close the valve port.

One of their main advantages is the energy saving available due to the ability to operate at low condensing pressures and allow precise superheat control. This in turn creates improved efficiency of the refrigeration cycle.

Due to their wide range of operation at various different pressures and the precision in terms of control, the use of an EEV allows for significant energy savings.

It has been proven that in commercial refrigeration and telecom control rooms, energy savings of 15% can be achieved and improved to 20% when using an E2V valve together with a floating condensing pressure control. Similar energy savings can be achieved in all types of DX applications operating year-round.