Frequently Asked Questions

FAQ HELP

Filter the questions using the category selector to the right.

ANALYSIS: My customer would like to get their refrigerant / oil / glycol analysed, can Climalife do this?

Yes we can carry out analysis on refrigerants, oils and glycols - please contact us for further information and pricing.

CLEANING: Do the Frionett® products have a smell or fragrance?

Unlike many similar products that leave a chemical smell behind, Frionett Activ leaves a pleasant mild pine smell that leaves customers knowing their systems have been cleaned. Frionett® Contact has no fragrance and is for use in areas where food is prepared.

CLEANING: Do your products kill the bacteria that causes smelly Air conditioning systems?

Both Frionett® Activ and Contact are approved to EN standards as bactericides and Fungicides to combat this problem, they are effective against Salmonella, Listeria, Legionella and Candida.

CLEANING: How safe is Frionett® to use and handle?

We recommend you make yourself familiar with and take note of the product data sheet for use and safety data sheet, however the Frionett® range are alkaline based cleaners and much safer to use than acid-based cleaners.

CLEANING: Your product data sheets recommends to rinse off after using Frionett®, do you have anything that does not require rinsing?

If it is not practical to rinse off after use, all that it will leave is a powdery residue, if this is acceptable then rinsing isn’t essential.

CLEANING: I would like to use just one product to clean inside and out what can you offer?

Given that the Frionett® Activ kills bacteria etc and this is not needed on outside units we developed Frionett® Power Ultra as an effective degreaser and to provide better cleaning power for external units, however either could be used on both if you preferred.

CLEANING: Are any of the Frionett® products carcinogenic, toxic or acidic?

The Frionett® range are alkaline based and much safer to use than acidic cleaners, they are neither carcinogenic or toxic either.

CLEANING: I have a chilled water system that someone has put tap water into and there are signs of corrosion and scale build up what can I do?

Desoxyclean is a powerful descaler and it deoxides metal surfaces, it is recommended to flush the system afterwards with Disperant D to clear out any residual product and or metal deposits.

CLEANING: Do you have anything that can clean out a newly installed system prior to filling with HTF for the first time?

Dispersant D can be used as a preventative measure before the first use of HTF if there is a risk of metal oxide or non-encrusted deposits in the system.

CLEANING: Is there anything I can use after a compressor burn out to clean the system?

Yes, depending on the size of the system Nettogaz GC+ can be used on systems up to 60kg’s and Facilisolv for larger ones.

CLEANING: I am converting an older system with mineral oil to an HFC that requires a POE oil is there something I can use to clean the system of the old mineral oil?

Yes, depending on the size of the system Nettogaz GC+ can be used on systems up to 60kg’s and Facilisolv for larger ones.

CLEANING: Is there anything I can use to sanitise a ground source heat pump HTF system to remove bacteria that may be present?

Thermonett® Sanitiser does this for new installations and the glycol we supply is bacteriostatic.

CLEANING: I have a ground source heat pump and the thermal fluid has degraded, is there anything I can use to clean it?

Thermonett® Flushing fluid will clean the system.

CLEANING: Is there a non-corrosive safer alternative to acidic descaler’s that I can use on heat exchangers etc?

Duonett® D7 is easier to use than conventional acidic descaling products, it is non-corrosive, produces no toxic vapour and doesn’t require special protective work wear.

CLEANING: I have a solar thermal system where the glycol has degraded to a sticky mess, is there anything I can use to clean it, or will I have to replace the whole system?

SolRnett has been specially developed to clean degraded solar thermal systems where the glycol has degraded, it dissolves and removes blockages and tar in such systems.

F-GAS: What is F-Gas Quota?

It is the amount of refrigerant expressed as CO2 equivalent Tonnes that each producer or importer is allowed to place on the market each year. The baseline for 2015 was set based on declared production and imports for 2009-2012. Once product is placed on the market by the producer or importer it can be resold to others.

F-GAS: How will F-Gas quota affect refrigerant supplies?

To facilitate a reduction in emissions of F-Gases as required by F-Gas legislation, there is a stepwise reduction in the amount of quota that can be placed on the market. It is expected that this will encourage and stimulate a move to lower Global Warming refrigerants. By 2030 the reduction will be 79% lower than the 2015 baseline.

HTFs: Do your glycols contain corrosion inhibitors?

Yes, we only sell glycols with corrosion inhibitors. It is very important that they do, as the use of uninhibited glycols will cause long term corrosion problems in refrigeration systems.

HTFs: Is the product food safe / food grade?

Heat transfer fluids are frequently used to lower temperatures in storage areas, manufacturing processes and the processing of food and drink. For consumer safety, it is necessary to select a non-toxic heat transfer fluid. There is no such thing as a “food grade” heat transfer fluid, or even one of “food-grade quality”. A heat transfer fluid is not a food-grade ingredient. There are however heat transfer fluids registered by the National Sanitation Foundation (NSF) for accidental contact with foods such as Greenway Neo N, a bio-sourced HTF from Climalife. NB: in the event of contact with a heat transfer fluid, the contaminated food product must not be placed on the market. NSF HT1 registration does not imply that the contaminated food product can be consumed.

HTFs: Why can’t I use tap water in my ground source heat pump?

Whilst water is technically a form of heat transfer fluid, it gives no protection from cold or metal corrosion. This is why it’s important to use a quality heat transfer fluid with both freeze and corrosion protection. Climalife’s range of heat transfer fluids each contain powerful hybrid inhibitors which can really help to protect the lifespan of a system. It is also recommended to use demineralised water when diluting a concentrated heat transfer fluid.

LUBRICANTS: Are there any tips for handling and storing lubricants?

We have produced a useful guide to handling and storing lubricants. Click to view

LUBRICANTS: What lubricants can be used with HFOs / A2Ls?

HFO and A2L refrigerants should only be used in equipment that is designed for use with HFO or A2L refrigerants and therefore the oil in the system should be suitable for use. If oil levels need topping up, it is recommended to use the same oil type or check with the compressor manufacturer if other lubricants are approved. In general, the same lubricants are used with A2Ls as with non-flammable HFC refrigerants. The majority of oils used will be POE based lubricants, but just as with HFCs, suitable PAG based lubricants could also be used. Some manufacturers of equipment using R-32 specify the use of PVE based lubricants but there are also suitable POE based lubricants for R-32. Some HFOs have a higher solubility in the oil which in a few cases may mean a higher viscosity oil is recommended compared to what would have been used with HFC refrigerants. Mineral and alkyl benzene based lubricants are not suitable for use with HFO and A2L refrigerants.

ORDERING: How do I place an order and what information does Climalife need from me?

We have created a handy Customer Order Request Form that you can use as a template or complete and send in to us by email at orders.uk@climalife.dehon.com. Please use this where possible as it means we can process your order more quickly. Our friendly customer services team can help you if you have any questions, just give them a call on 0117 980 2520.

Please note an order is not a confirmed order until you receive confirmation back from us. We do not currently offer online ordering.

ORDERING: Where is my delivery? Where can I find a price? How can I check stock levels?

Our customer services team can help you with each of these questions. Get in touch by phone (if urgent) on 0117 980 2520 or by email at orders.uk@climalife.dehon.com. All orders need to be in before 3pm.

ORDERING: How does the process work?

You can view our business process for working with us here

ORDERING: Will Climalife supply anyone?

We are a responsible supplier who supply through the trade and to contractors who can demonstrate themselves to have a minimum level of competency in handling our products. For HFCs we require contractors and their engineers to hold the relevant F-Gas certificate before we will supply, as it is illegal for them to use these products without such certification.

PRODUCT INFORMATION: Where can I find safety data sheets and other product information?

All product information, including Product Data Sheets, Safety Data Sheets (MSDS), case studies and brochures can be found on their respective product page.

If you are an existing customer, you are also eligible for access to our Customer Resource Centre which holds additional product information, not available on our website. Contact us for access at climalife.uk@climalife.dehon.com.

RECLAMATION: Do you provide a reclaim/recovery service?

Yes we do, we can supply 750kg drums, 50kg large or 10kg small cylinders. When returning product for reclamation we can help you to comply with the current hazardous waste regulations. Please contact us for more information.

REFRIGERANTS: How do I track my cylinders?

We issue monthly cylinder statements on the first weekday of every month. You can request your own login access to track your cylinders. Contact us for information and access either by phone on 0117 980 2520 or email.

REFRIGERANTS: How do I go about arranging cylinder collection?

To arrange the collection of refrigerant cylinders, please complete one of our Cylinder Collection Request forms. View and download the Cylinder Collection Request form here.

REFRIGERANTS: What is the difference between reclaimed and recycled refrigerant?

Recycled refrigerant is product that has gone through a basic cleaning process; this can be a pass through a drier and a filter. There is no analysis or quality assurance about recycled product, which could be long way outside of the specification of virgin product. Reclaimed Refrigerant however, has gone through a thorough cleaning process to remove moisture, oil, particles, etc. The product will be analysed and will meet the same specification as virgin product.

REFRIGERANTS: Can I use R-404A in new equipment?

No - the use of R-404A in new stationary refrigeration equipment where product temperatures are -50°C or greater was banned from 01/01/2020. Lower GWP refrigerants, R-448A, R-449A and R-452A are potential replacements in direct expansion systems. Please contact Climalife for specific recommendations for your applications.

REFRIGERANTS: I have heard that the use of R404A for servicing is banned from 2020, is this true?

Yes the new F Gas Legislation that came into force on 1st January 2015 prohibits the service and maintenance of stationary refrigeration systems with virgin refrigerant with a GWP equal to or greater than 2500, for systems where the charge is greater than 40T CO2 equivalent (10.2kg of R-404A).

REFRIGERANTS: Which refrigerants have a GWP over 2500?

R-404A, R-507, R-434A, R-422A, R-422D, R-428A, R-125, R-508B, R-23 and ISCEON MO89.

REFRIGERANTS: When you get a leak from a system containing a blend do you have to remove the remaining product and charge with virgin product?

Although there may be occasions with some refrigerants where this may be necessary, in the vast majority of cases, it is possible to top up with virgin product and return the product to specification. If the performance of the refrigerant is worse than expected, then it may be necessary to replace the charge. Our experience with a number of blends including the ISCEON 9 series has shown that up to 80% can be lost before the composition changes significantly. There is documentary evidence on producer websites that suggest you can top up refrigerants including R-407C, without any significant loss of performance.

REFRIGERANTS: Do blends separate?

Blends do not separate into their individual components; however, the composition of a blend can change if they are not handled correctly. We always strongly advise taking refrigerant blends from the cylinder in the liquid phase only and ensuring leaks are kept to a minimum.

REFRIGERANTS: Where can I get thermodynamic data for refrigerants?

Please go to our download section. Detailed thermodynamic data for the ISCEON 9 series is included in the retrofit guidelines for the appropriate refrigerant.

REFRIGERANTS: Why can't R32 be used in R410A equipment?

R32 should only be used in equipment designed for its use. It is not a retrofit or a top up option for R410A. Whilst the main reason is safety, as R410A equipment is only desgined for a non-flammable refrigerant, the operating characteristics of the two refrigerants are different.

REFRIGERANTS: Can I use normal traffic cylinders for reclaim?

No. It is important to retain the integrity and cleanliness of normal traffic cylinders. Product reclaimed from systems will contain moisture, oil and acid to varying degrees. Climalife supply reclaim cylinders specifically for the purpose and are fitted with a dual port valve which aids the recovery process. Please contact us for further information.

REFRIGERANTS: Can I still use R22 for service and maintenance? What can I use to replace R22?

No, in the EU it is illegal to use R22 for service and maintenance. The use of virgin HCFCs was banned in the EU at the beginning of 2010 and the use of reclaimed and recycled refrigerant was banned on 1st January 2015. Whilst systems on R22 can be kept running, it is illegal to top up a system with R22 or other HCFCs. See our Legislation page for more information and check our recommendations for converting HCFC refrigerants to other refrigerants.

R22 replacement: it depends on the type of system, as to which refrigerant is best for the application. We can make recommendations for specific applications depending on the circumstances. However, ISCEON MO99 (R438A) can be used in most Dx refrigeration, air conditioning and chiller applications to replace R22. We always recommend the conversion guidelines are consulted and followed. More information on R22 replacements can be found on the product page and in the Download section.

For further advice get in touch with your Sales Manager.

TECHNICAL DATA: Where can I find the SDS / Safety Data Sheet for a particular product?

MSDS / SDS / Material Safety Data Sheets / Safety Data Sheets are stored within the individual product pages. Search for the product first and then click through to the document you need. If you cannot find a document, please contact us.

If you are an existing customer, you are also eligible for access to our Customer Resource Centre which holds additional product information, not available on our website. Contact us for access at climalife.uk@climalife.dehon.com.

TECHNICAL DATA: Where can I find a technical data sheet / product data sheet for a particular product?

Technical Data Sheets (TDS) are stored within the individual product pages. So search for the product first and then click through to the document you need, If you cannot find a document, please contact us.

If you are an existing customer, you are also eligible for access to our Customer Resource Centre which holds additional product information, not available on our website. Contact us for access at climalife.uk@climalife.dehon.com.

TECHNICAL TERMS: Explain CO2 equivalents

The GWP value of substances is a simplification of the radiative efficiency values (warming effect) and compares everything to a unit of mass of carbon dioxide (CO2) over a set period of time, e.g. R-404A GWP = 3922 which means 1kg of R-404A has the equivalent warming impart of 3922kg of CO2 or to put it another way 1 kg of R-404A has 3922 CO2 equivalents (CO2e).

Since 2006, manufacturers and importers of F-Gases have had to annually declare the quantity of each F-Gas placed on the market. In 2015, the second F-Gas regulation was put in place and this introduced a HFC phasedown with the starting quantity calculated based on the average of the 2009 to 2012 HFCs placed on the market, expressed as CO2 equivalents. This allowed the user to choose the refrigerant, as long as the total CO2 equivalent of the refrigerant used was within maximum quota.

Since leaving the European Union Great Britain has continued the phasedown using a new baseline for the consumption within GB only. Moving into the future, the RAHCP and other industries using F-Gases have to move from high GWP refrigerants to low GWP refrigerants. Current legislation estimates that average GWP of F-Gases used in 2022 should approximately be 900, decreasing to 600 in 2024 and finally reaching the low level of 400 by 2030. What is the average GWP of the refrigerant you use?

For advice on refrigerant strategy talk to the experts at Climalife.

Date added: August 2022

TECHNICAL TERMS: What is COP?

COP is the abbreviation often used for Coefficient Of Performance which describes the energy efficiency of a system. It is the ratio of the energy input to the energy output which for most RACHP applications relates to the electrical input compared to the heating or cooling capacity achieved. For example, if a refrigeration system is providing 2 kW of cooling capacity but consuming 1 kW of electricity then the COP is 2 (2/1). If the electricity input was just 0.5 kW for the same 2kW of cooling, then the COP would be 4 (2/0.5). The higher the COP value the better the energy efficiency. COP is an instantaneous measure of energy efficiency and will vary with the operating conditions. COP normally only considers the power input to the compressor but can be extended to included other power consuming components, e.g. fans, and referred to as System COP.

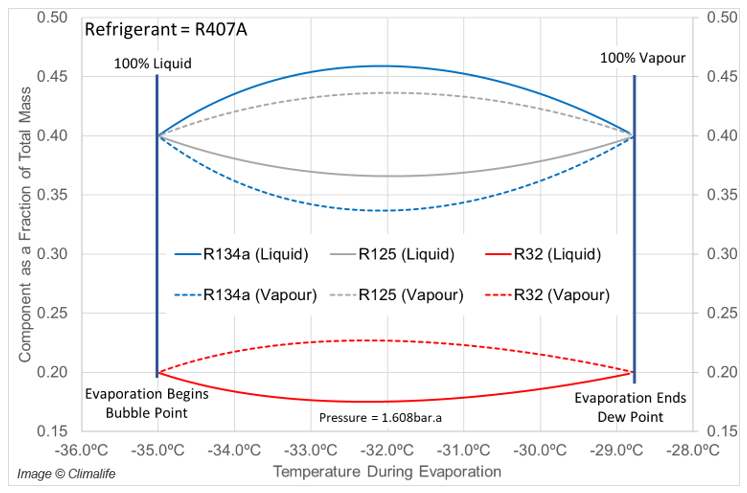

TECHNICAL TERMS: What is temperature glide?

When a single component or azeotropic mixture boils at constant pressure, the liquid temperature at the inception of boiling (bubble point) is the same as the temperature of the last drop of liquid as it turns to vapour (dew point) at the end of the boiling process. For these types of fluids, the composition of the liquid and vapour are also the same throughout the boiling process.

In RACHP this process is normally referred to as evaporation. With single components or azeotropic mixtures the temperature difference from beginning to end of the change from liquid to vapour is 0, i.e. there is no temperature glide.

When a non-azeotropic mixture (all R-4XX refrigerants are non-azeotropic) boils (evaporates) there is a rise in temperature between the bubble point and the dew point and this change in temperature is called the temperature glide.

The temperature change is due to a composition difference between liquid and vapour phases during the boiling process causing the boiling point of the liquid phase to rise. It is important to note that in a direct expansion (DX) application, although the composition of the liquid changes during the boiling process, the composition of the vapour as it leaves the evaporator will be the same as the liquid composition that enters the evaporator, as shown in the following figure using R-407A as an example.

WASTE: How do I get details of the environment agency hazardous waste regulations?

Please see waste management section and legislation section.