Cool Gauge RT100 helps aerospace engineering company to control HTF dosing to an Adiabatic Cooling System

Climalife UK

The system and historical problem

It was identified that the site’s ‘production critical’ adiabatic cooling system required greater control and management.

It was identified that the site’s ‘production critical’ adiabatic cooling system required greater control and management.

One of the key parameters that needed to be kept under strict control was the HTF level. By monitoring and controlling the optimum HTF (inhibited) reserve, the system can receive the necessary protection from freezing, corrosion and scale.

One of the key parameters that needed to be kept under strict control was the HTF level. By monitoring and controlling the optimum HTF (inhibited) reserve, the system can receive the necessary protection from freezing, corrosion and scale.

The solution and its management

Continuous collection of vital HTF data by Cool Gauge is now delivered to the controller via Cool Gauge’s RS485 capability which effectively enables accurate dosage of the selected HTF to the system.

Continuous collection of vital HTF data by Cool Gauge is now delivered to the controller via Cool Gauge’s RS485 capability which effectively enables accurate dosage of the selected HTF to the system.

The HTF reserve is maintained accurately by adjustable high and low set-points in the controller. This data can also be seen by remote viewers in real-time, and, if necessary, alerts sent to operators via text or email if the set-points are breached. This facility warns operators of any impending problems such as drops in the HTF level due to leaks.

The HTF reserve is maintained accurately by adjustable high and low set-points in the controller. This data can also be seen by remote viewers in real-time, and, if necessary, alerts sent to operators via text or email if the set-points are breached. This facility warns operators of any impending problems such as drops in the HTF level due to leaks.

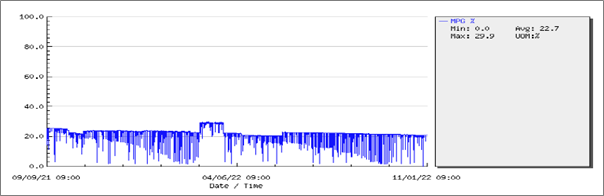

The graph above shows data as viewed by operators after logging in to the cloud account. It can be seen that steady HTF conditions are maintained over the 13-month timescale selected.

Fluctuations, such as those seen if a manual shot dose of HTF is made, can be easily noted as a rise in the monitored level. The on-going HTF system average is shown in the grey box. Any historical data can also be seen by adjusting the start and finish dates in the cloud website.

This case study is an extract from the full development report produced for the client - it can be viewed here.