Safety / Environment : essential criteria when choosing a heat transfer fluid.

Heat transfer fluids are antifreeze and inhibitor-based and come in concentrated solutions for dilution with water, or as ready to use.

The antifreeze protection of a heat transfer fluid is the first criterion to take into account, but it is essential to look beyond this by taking safety and the environment into consideration. Indeed, the formulation basis has an environmental impact by virtue of the source of the raw material, its production and not forgetting its biodegradability. It also has an impact on personal safety, thermodynamic systems and on their implementation (whether they are harmful or harmless).

The formulation bases of heat transfer fluids determine the characteristics and physical properties used to size the installation (viscosity, compatibility, etc.) and its performance (heat exchange, bacteriostatic, etc.). The ecological footprint of an installation may be reduced by choosing a heat transfer fluid with low viscosity which minimises energy consumption.

1. Safety: Reading material safety data sheets (MSDS)

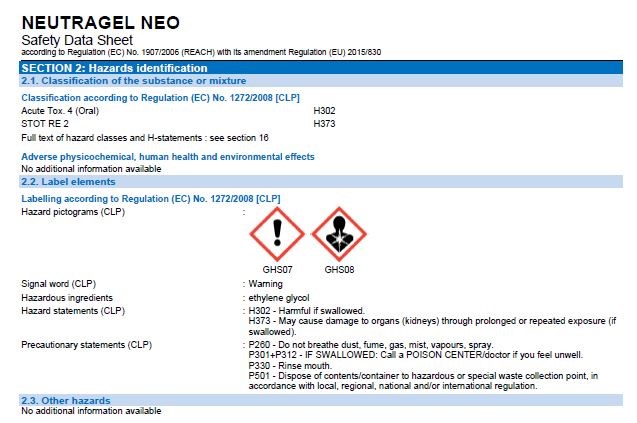

Reading material safety data sheets is not always easy, but it is the first thing you should think about. In particular, you should look at the hazard pictograms and read the physical hazard phrases, for health and the environment (H) and precautions (P) in section 2.

All the MSDS for Climalife products are available on our website and on quickfds.com

Example : Extract of a MSDS for a heat transfer fluid based on MEG (image 1) and a MSDS based on MPG (image 2).

Image 1

Image 2

2. Safety: Toxicity and harmfulness of heat transfer fluids

As seen in the examples, a number of formulation bases are available on the market. Depending on the application (refrigeration, air conditioning, heating, etc.) and the industry (food processing, construction, chemistry, etc.), the selection of heat transfer fluid must take account the toxicity of the formula. Indeed, choosing a heat transfer fluid based on MEG (harmful), will only be possible in the case of applications where there is no risk of contact with food products or substances, or sanitary water supply, even accidentally.

In order to limit the impact on human health, a bittering agent is present in our MEG-based heat transfer fluids to avoid any risk of ingestion. In addition, all Climalife heat transfer fluids are nitrate- and amine-free to avoid the formation of harmful compounds such as nitrosamines.

Climalife also bans the use of phosphates and borates as well as all other CMRs (Carcinogenic, mutagenic and reprotoxic agents/substances) in its formulations.

3. System Safety

In order to prevent wear and attack on installation components, it is essential that the heat transfer fluid selected contains a package of inhibitors to combat corrosion and limit the risk of leakage. On the other hand, when diluting a concentrated heat transfer fluid, it is important to use demineralised water in order not to import contaminants when starting the system.

The operating temperature ranges must also be adhered to. Depending on the base of the selected heat transfer fluid, this may range from -55 °C to +200 °C. Climalife offers a range of heat transfer fluids covering all temperature ranges.

In a solar system, for example, the heat transfer fluid circulates in the primary circuit of a heating or hot water system and in solar thermal panels which may be subject to high temperatures, in particular during periods of stagnation when the system is shut down.

The formulation base of bio-sourced 1,3-propanediol of the Greenway® Neo Solar N, which is very stable at high temperatures, causes only a slight deterioration in the circuits and reduces ageing. It prevents “tarring” of the sensors and circuits and increases the lifespan of the installations. At +150 °C for 150 hours, Greenway® Neo Solar N degrades 3 times slower than a 50% of Mono Propylene Glycol solution.

4. Consumer Safety

The Greenway® Neo N formula is NSF HT1 registered

The formulation of the range of Greenway Neo® heat transfer fluids, acclaimed by the market since 2010, has changed. Greenway® Neo is now NSF HT1 registered for accidental food contact and is now called Greenway® Neo N. It maintains the same heat transfer efficiency as the previous formula and, in particular, meets all requirements for food processing applications.

This new formula will be available in 2021.

In addition, Greenway® Neo N has a viscosity less than that of conventional heat transfer fluids (with MPG base) and can reach temperatures as low as -50 °C which is not possible with a MPG.

In certain cases, it is possible to reduce the size of piping and pumps thus leading to a reduction in energy consumption.

Focus on food applications

Heat transfer fluids are frequently used to lower temperatures in storage areas, manufacturing processes and the processing of food and drink. For consumer safety, it is necessary to select a non-toxic heat transfer fluid.

It should be noted that there is no such thing as a “food grade” heat transfer fluid, or even one of “food-grade quality”. A heat transfer fluid is not a food-grade ingredient. There are however heat transfer fluids registered by the National Sanitation Foundation (NSF) for accidental contact with foods.

NB : in the event of contact with a heat transfer fluid, the contaminated food product must not be placed on the market.

NSF HT1 registration does not imply that the contaminated food product can be consumed.

Further details on sanitary hot water applications

Climalife offers a range of heat transfer fluids for applications that may be in contact with sanitary hot water (SHW, i.e. heated water used for domestic purposes routed via pipes to the points of use (shower, washbasin, dishwasher, etc.).

There are several techniques for heating SHW, such as heat exchange with a loop of water (from a solar source for example) which is hotter than the water to be heated.

In order to limit risks associated with accidental ingestion in the event of leaks to the SHW, Climalife has added a bittering agent to the Greenway® Neo Heat Pump N and Greenway® Neo Solar N.

The formulation bases of Climalife heat transfer fluids

- Bio-sourced 1,3-propanediol

- Mono propylene glycol (MPG)

- Mono ethylene glycol (MEG)

- Potassium acetate and formate

- Betaine

Did you know ?

With formulae based on renewable plant based raw materials, the Greenway® Neo N product range provides environmental consistency.

Plus, the life cycle analysis* shows that its production offers significant environmental advantages: less greenhouse gas emissions (-56%) and less non-renewable energy (-38%) used in production compared with conventional heat transfer fluids based on fossil fuels (petroleum) such as the MPGs.

*The Life Cycle Analysis is an analysis which takes into consideration the environmental impact of the product from cradle to grave.

Bio-sourced 1,3 propanediol : raw material of the Greenway® Neo N range

Greenway Neo N is a heat transfer fluid based on bio-sourced 1,3 propanediol, Susterra® approved by NSF International (Proprietary Substances and Nonfood Compounds) is a component suitable for use in heat transfer fluids in the event of accidental contact with foodstuffs (Category code: HTX-1; NSF approval number: 141749) to be used in the immediate vicinity and within foodstuff conversion areas in compliance with good manufacturing practice.

Moreover, it is recognised as safe by the Food and Drug Administration (FDA) in the US in section 21CFR184.1666 and meets the specifications of the Food Chemicals Codex, 6th edition (2008).

1,3 propanediol is classified as E1520 in an amendment to directive 95/2/CE of the European Union, which regulates human foodstuff additives, and is listed in appendix I of regulation (UE) no.10/2011 of the Commission as a monomer and additive authorised for materials and objects in plastic intended to come into contact with foodstuffs.

The Greenway Neo N range will be coming very soon to market in the UK.