Putting the spring back into your system

Climalife UK

With the arrival of Spring, we can start to look forward to longer days and warmer weather. Tradition tells us that it’s the time to spring clean our homes, workplaces and equipment, but so often other priorities can get in the way, and we put off taking action.

Having a year-round maintenance programme in place can maximise system performance efficiency and save money. It is also important to use good quality cleaning products, that are suited to the individual system elements and needs.

The importance of preventive maintenance

The energy efficiency of heating and refrigeration installations depends firstly on choosing the right technology and then, as the years go by, the regular maintenance of exchangers and all fluid and air handling systems. It is vital that air-based heat exchangers, such as evaporators and condensers, as well as filters and ducting systems are kept clean.

During operation a drop in heat transfer caused by fouling of heat exchanger surfaces affects the refrigeration unit’s capacity leading to extended compressor run times, which in turn increases energy consumption. To maintain any system, preventive treatment is an ideal solution to limit the risk of scaling and oxidation in the hydraulic systems and prevent the risk of clogging in the heat exchangers. This will stop a drop in thermal exchange and of the flow of transfer fluids. Clogging will also affect a system’s lifetime as well as a loss in performance.

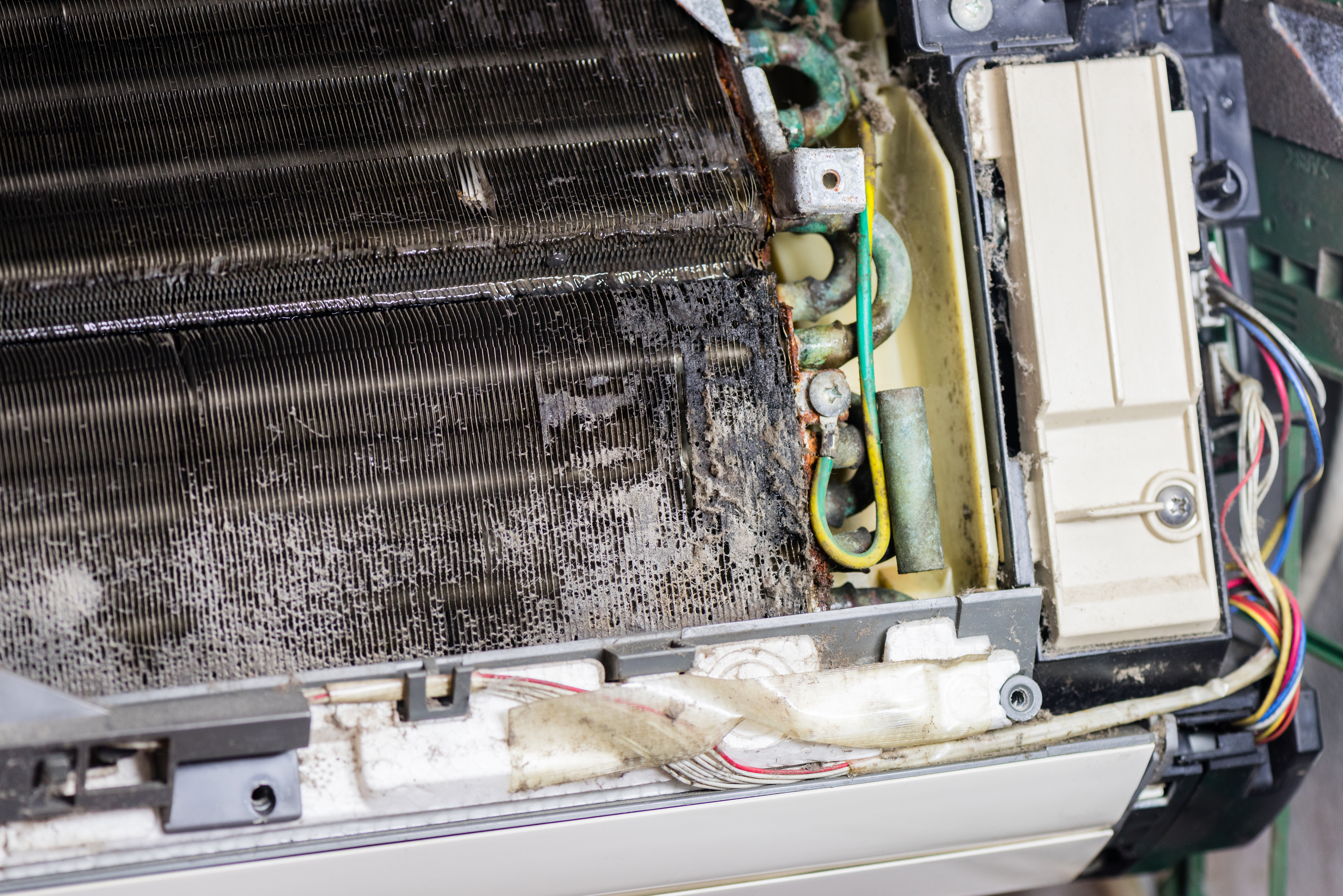

Dirty air conditioner coil

Periodic Oil Analysis is available from companies like Climalife to monitor the condition of your refrigeration installations on a preventive basis and to check for and avoid pollution within the system. A quick on-site acid test using a product such as Acitest Unipro WW, can give an immediate indication on an oil running in the system and could prevent system failure.

On external surfaces, the clogging of evaporators and fin condensers can cause energy issues as well as hygiene problems and health risks. There are many cleaning products on the market: solvents, aqueous solutions, biocidal solutions, fungicides and bactericides. Frionett® Activ’ from Climalife is a good all-round cleaning and disinfecting product, designed to maintain refrigeration and air-conditioning installations (for large surface evaporators and internal units). Formulated to fight bacteria and fungi, Frionett® Activ’ cleans deeply and eliminates offensive odours.

Curative measures for equipment

Refrigeration systems

A refrigeration compressor could fail for many reasons. Two common causes are either breakdown of materials in the refrigeration system due to excessively high compressor discharge temperatures or excessive moisture present in the system. Presence of water causes hydrolysis of oils and forms acid that causes oxidisation. This can lead to accelerated wear and corrodes the lacquer (epoxy resins) in the electric motor. The windings then become exposed, which creates a short-circuit that causes the refrigerant to break down, raising the acidity in the system even further. Unless you clean the line, this acid remains in it and the new compressor will fail for the same reasons. If faced with a situation like this, it is essential to clean the line with a solvent that can remove the acids and carbonised particles to ensure the installation continues to work effectively and efficiently. If a compressor suffers a mechanical failure, the metal particles distributed through the line must be cleaned out in the same way. Consider using a product such as Facilisolv from Climalife.

The cleaning of the interior of refrigeration systems following an incident (failure of a compressor, electrical motor burn-out, presence of water or moisture) needs to be approached appropriately.

For hermetic compressors and semi-hermetic compressors, the presence of acidity after motor burn-out or the presence of moisture in a circuit will result in the burn-out of the electrical motor and oxidation.

The best way to clean a system after a compressor failure or burn-out is to remove the oil in the system. It is oil that represents most of the pollution and particles (moisture, acidity). A product such as Climalife’s Facilisolv can be considered to achieve this. It is worth conducting full oil analysis at this time, which may identify the cause of any issues in the system.

When water enters a refrigeration system following a water-based heat exchanger failure, before any cleaning can take place, the compressor and faulty exchanger must be demounted. The faulty equipment will have to be changed or repaired and then the water will have to be purged from the system, section by section, with refrigeration-grade nitrogen. The unit will then have to be evacuated to 0.3 mbar and cleaned with the solvent or cleanser selected. Finally, the compressor is replaced or repaired.

In the case of an installation containing small amounts of moisture or acidity, the oil and drying or anti-acid cartridges should be replaced once or more depending on the amount of contamination.

Secondary heat transfer systems

In a closed-circuit water system, such as those used in ground source heat pump systems, chilled-water or heating-water system, corrosion and limescale can create performance problems, costing time and money. Prevention measures can be taken by cleaning the system with products designed to protect the system against corrosion and limescale.

Heavily scaled tube

Open circuits such as cooling towers, municipal water or ground source water systems and sometimes closed heating systems need to be descaled thoroughly before any sludge and oxides can be removed. Duonett® is an industrial descaling product and Desoxyclean removes sludge and oxides, both available from Climalife and ideal for these operations.

In solar panels, caramelisation can occur during long periods of stagnation which can degrade system performance. A product such as SolRnett from Climalife is specifically formulated to tackle this problem and restore the circulation in the circuit.

In summary

There are many solutions on the market including an great range from Climalife, that can tackle poor performing system issues, however a regular maintenance programme, combined with good gas detection should be the number one priority of all system owners. It makes both good economic and good environmental sense. Cleaning and analysing the quality of technical fluids in a system is one of the most important ways that you can prolong the life of any existing equipment, so with Spring approaching, let’s make it time to get our systems checked, cleaned and working as efficiently as possible.

© climalife 2024