The ‘F’ Word – Tackling A2L Flammability

Climalife UK

Over the last few years there has been an increasing amount of very low GWP refrigerants available in the market and new products continue to be developed each year.

Allan Harper, Climalife UK Managing Director discusses…

The main driver behind the development and introduction of these new refrigerants is their low global warming potential. Refrigerants all have a value relative to CO2 as the baseline, for their global warming potential and there is increasing pressure for the GWP value to be reduced in order to meet both the F-Gas regulation and the UK carbon emissions net zero 2050 target.

By 2030 the current F-Gas Legislation requires the CO2 equivalent tonnes of refrigerant being placed on the market to be reduced by 79% from the baseline figure set in 2015. To meet the phase down steps, the move to even lower GWP products needs to gather pace and will require the greater use of A2L refrigerants.

The very low GWP A2L refrigerants need to be used in new equipment and this has already started to enter the market to meet the requirement for transitioning to A2L refrigerants.

So, if the products are available and the new equipment has come to market then why aren’t we all transitioning to A2L’s straight away? Well, a big part of this is where the ‘F’ word comes into it – Flammability.

The A2L Classification – What it means

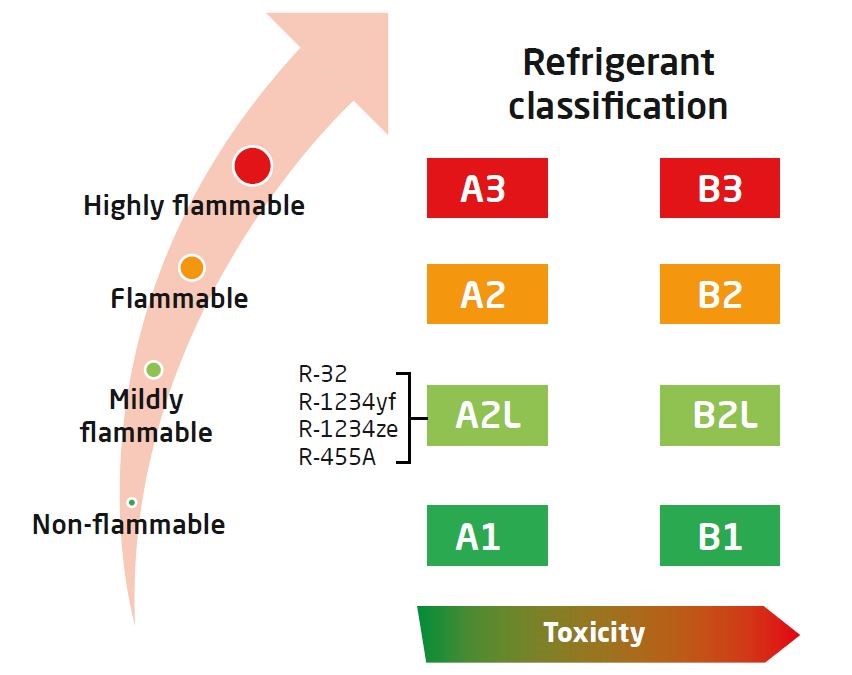

These low GWP refrigerants are usually flammable, which gives them their ASHRAE classification of A2L.

ASHRAE Classification

Most of the commonly used HFC and HFC/HFO blend refrigerants are classified as A1 meaning that they have very low toxicity and zero flammability.

The term A2L refers to a safety classification based on ISO 817 and ASHRAE Standard 34 for toxicity and flammability. Toxicity is divided into two categories, A for lower toxicity, B for higher toxicity, whilst flammability is divided into four groups; 1, 2L, 2 and 3; assigned depending on several flammability parameters including Lower flammability Limit (LFL), Heat of Combustion and Burning Velocity. 1 is non-flammable, 2 is lower flammability, 3 is higher flammability, whilst the 2L category is often referred to as mildly flammable. and has a requirement that the burning velocity must be 10cm/sec or below. For example, R-32 has burning velocity 6.1 cm/sec and R-1234yf 1.5 cm/sec.

The overall difference between A1 refrigerants such as R-410A and A2L refrigerants such as R-32, is that the A2L refrigerant has the ability to propagate a flame in the right circumstances. The refrigerants will burn, but the burning velocity will be 10cm/sec or lower.

Flammability – Mitigating the risks

A crucial step for achieving a level of risk that is as minimal as possible, is having adequate risk management in place.

One of the first steps to minimising the risk is to avoid the release of refrigerant from the cylinder or the system. This involves safety procedures being in place from the moment the cylinder is filled and transported to when it is being installed and the system serviced.

Providing the concentration level remains below the lower flammability limit (LFL) and above the upper flammability limit (UFL), then a flammable refrigerant will not ignite. Safety standards such as ISO 5149 and EN378 specify that they should remain well below the LFL to reduce any risks in case of system leaks, therefore it is important that standards are closely followed when using A2L refrigerants to charge systems.

All applications should have a valid risk assessment whatever classification the refrigerant falls into, however a critical stage of conducting a risk assessment for an A2L refrigerant should be to identify any possible scenarios where an ignition source could be present along with a concentration of leaked flammable refrigerant. A2L refrigerants present no risk during normal operation when the refrigerant is contained within the system.

However, if the refrigerant was to leak and only if the leak is large enough for it to accumulate into a flammable concentration where an ignition source is present at the same time and location, then the refrigerant could ignite. So, it is important that all risks are assessed in advance and that where a sufficient risk is identified leak detection is used to catch any leaks as soon as they occur.

Even for A1 refrigerants, if you did not adhere to all of the product safety guidelines and best practices for installation and servicing, when released, they can cause safety risks. Providing the risks are understood and assessed accordingly, then installing and servicing an A2L refrigerant should be very little difference to that of an A1 refrigerant.

Training in the handling of flammable refrigerants is key

R-32 and R-1234yf are both A2L rated refrigerants and both have gained extensive traction for split AC and Car AC. In order for the uptake of A2L’s to increase, other sectors need to ensure engineers are trained to safely work with and handle flammable and mildly flammable refrigerants.

Like other new refrigerants in the past, initial problems and concerns are soon overcome as experience and knowledge is gained. There is plenty of guidance from trade bodies on handling flammable refrigerants, including advice on risk assessment, whilst EN378 also provides guidance on charge size requirements and what can be achieved with mitigating circumstances and additional safety measures to achieve larger charge sizes.

It is critical that A2L refrigerants are only used in systems specifically designed to account for their flammability. A2L refrigerants should never be used to retrofit non-flammable refrigerants in a system that has not been assessed and deemed safe for use with a flammable refrigerant.

Future Steps

Understandably, the word ‘flammable’ is bound to create a level of unease for some people, but what is important is to look beyond this and really evaluate what it means in practical terms for the industry and the F-Gas phase down.

In order to meet the next F-Gas phase down step of 29% in 2021 from the level available in 2020 for refrigerants that can be placed on the market, it is essential that we continue to move to using refrigerants with much lower GWP.

There are a number of studies that have been published which show that A2L refrigerants are more energy efficient than the other low GWP technologies. With refrigeration and air conditioning equipment attributed to consuming 17% of total electricity demand, energy efficiency is going to be a very key topic over the coming years in the climate change debate as we move to a carbon neutral economy.

A2L refrigerants will be key in the quota management process as the full effects of the HFC phase down begin to be felt. If best practice, good guidance, regulations and standards are followed when handling and installing A2L refrigerants, then there is no reason as to why A2L refrigerants cannot be used safely and easily in a large range of applications.