Standards & Regulations : Keeping your systems operating safely, but only if you know what they say

Climalife UK

Standards and regulations have been an important aspect of the refrigeration, air conditioning and heat pump (RACHP) industry for many years. Regulations such as the ozone protection regulations, and latterly the F-Gas regulations, have been well publicised and largely self-policed within the industry but there are many other regulations and standards which have been in place in one form or another just as long but have been less publicised and often less well observed.

After the introduction, in the 1930s, of fluorocarbon-based refrigerants, which exhibited low toxicity and were essentially non-flammable, it was often seen as less important to refer to standards and regulations because of the inherent low risk that was perceived using these “safe” refrigerants. The fact is that all commonly used refrigerants are classified as hazardous, and standards and regulations must be followed to try to prevent any accidents from occurring.

This has become even more important in recent years since the realisation that high global warming potential (GWP) refrigerants are contributing to climate change and many of the very low GWP alternatives either have a much higher toxicity, a degree of flammability or explosively high pressure. We have been promoting the use of low GWP refrigerants, many of which have the A2L (lower flammability) safety classification, for over five years, and in many cases it has been very evident that the application and sometimes knowledge of the relevant standards is somewhat lacking.

The industry as a whole needs to ensure that they are aware of what standards and regulations are relevant and, most importantly, apply them to every installation. When talking to potential users of very low GWP options the application of the EN 378 standard and the Pressure Equipment Safety Regulation (PE(S)R) is often seen as an additional step or consideration but these both apply to any refrigerant and should always be considered.

There are many standards and regulations that apply to the RACHP industry but in the course of my discussions, there are a few particular parts of these that are very important with regard to refrigerant choice, which either do not appear to be well understood or are seen as additional and arduous to comply with.

F-Gas Regulation

The current F-Gas regulation has been in place since 2015 and has driven the industry to lower GWP refrigerant options but the carbon dioxide tonnes equivalent (CO2Te) phasedown still has a long way to go and most of the ‘easy wins’ have already been implemented. To achieve the final 30% reduction in CO2Te required under the current legislation, in many cases it will be necessary to use refrigerants with different safety or physical properties to those previously used.

The F-Gas regulation set out timelines that gave the industry time to plan their move away from higher GWP, and whilst larger organisations have done this, there are still many who are just waiting until the higher GWP refrigerant availability becomes difficult with no thought to how to keep the existing equipment operating for its full useful life. Until now, when previous legislation has restricted the use of certain refrigerants there has always been a retrofit option available but this time around it is very unlikely there will be a suitable retrofit option available which will be compliant with other regulations and standards, unless that has been planned at the time of installation.

EN 378

EN 378 covers a number of safety requirements for RACHP systems and applies to systems that are not covered by specific equipment standards e.g. EN 60335-2-40 (AC and Heat pumps) or EN 60335-2-89 (self-contained plug-in refrigeration units).

EN 378 covers a number of safety requirements for RACHP systems and applies to systems that are not covered by specific equipment standards e.g. EN 60335-2-40 (AC and Heat pumps) or EN 60335-2-89 (self-contained plug-in refrigeration units).

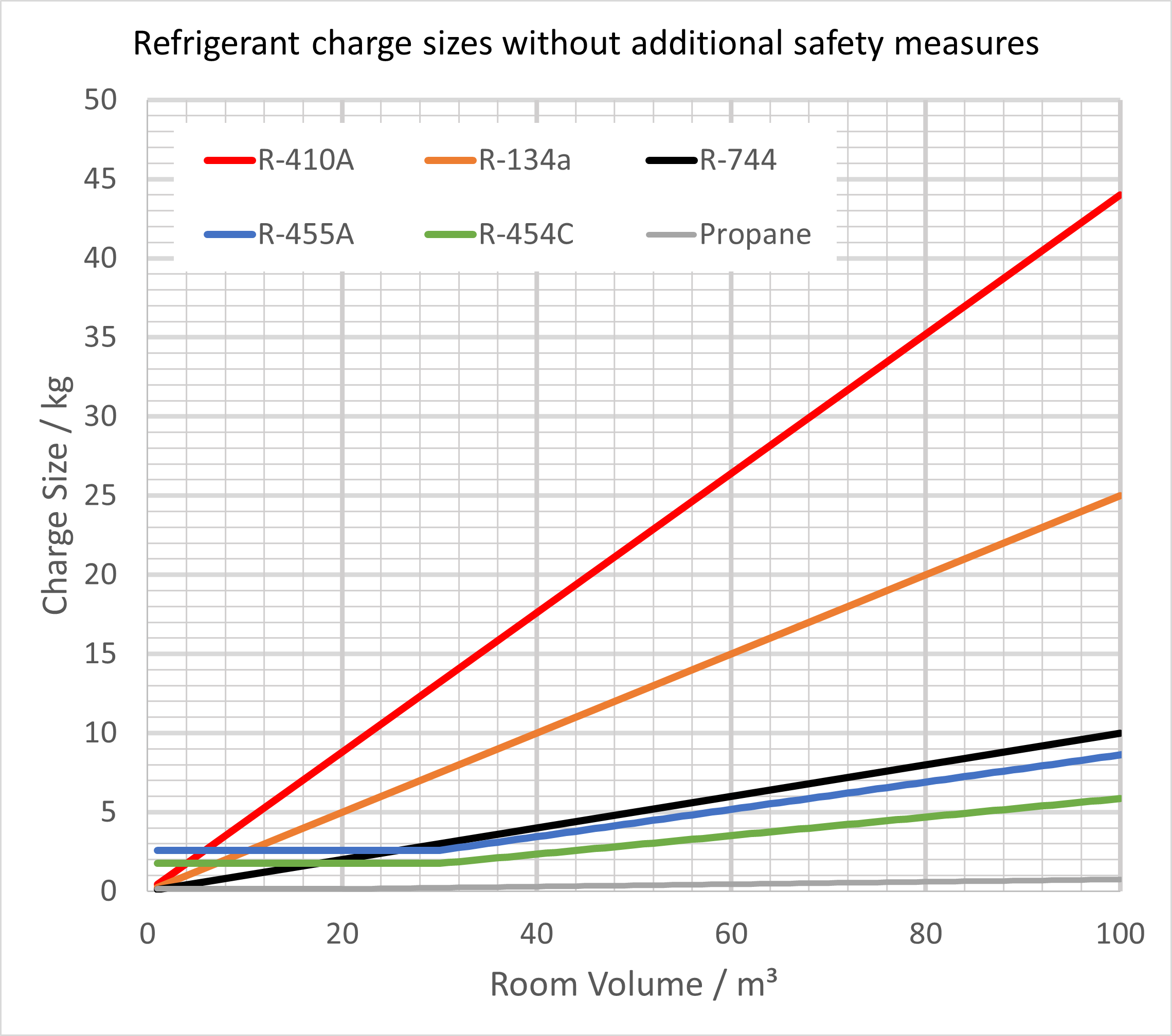

When considering moving from an A1 safety class refrigerant to flammable, higher toxicity or higher pressure refrigerant, one of the most important considerations is the impact on refrigerant charge size. This applies to all refrigerants but for many A1 refrigerants it was overlooked, even though in systems running from a central pack with one or multiple small rooms attached, if a refrigerant leak occurred in one of those rooms, it was almost inevitable that the practical limit would be exceeded. As can be seen in the figure 1, the compliant refrigerant charges (without additional safety measures) with all the low GWP options are considerably smaller than when using the higher GWP refrigerants which is one reason they are unlikely to be suitable as a retrofit option in existing equipment.

There is no real substitute for learning the content of EN 378, or any other relevant standard, but there are various tools available to help make charge size calculations like the online app from Climalife (www.a2l.climalife.com).

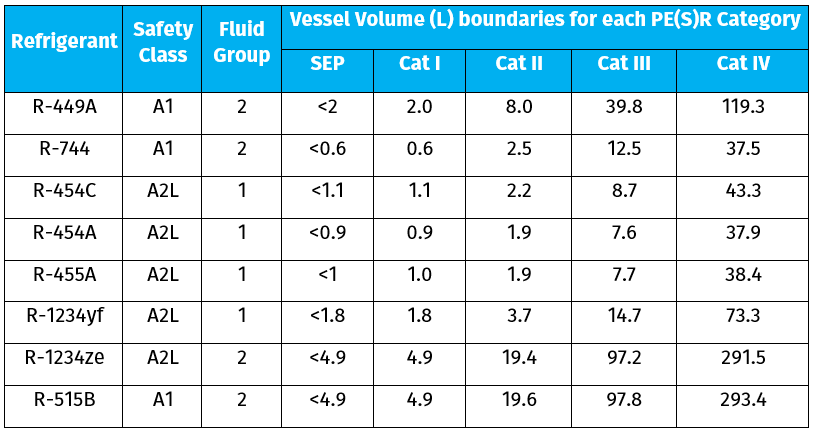

PE(S)R

PE(S)R is the UK regulation covering the Pressure Equipment Directive (PED). Under the current legislation refrigerants are classified into two groups where all refrigerants with a degree of flammability are in fluid group 1 and non-flammable refrigerants are in fluid group 2. In most cases this is the main reason the very low GWP refrigerants that have a degree of flammability cannot be considered as retrofit options. Moving from a fluid group 2 option (non-flammable) to a fluid group 1 (flammable) option will in many cases raise the PE(S)R category with the result that maintaining compliance with the regulation often becomes practically impossible. Meeting the requirements of PE(S)R is often only feasible at the time of manufacture and therefore it is critical that only components designed for the refrigerant are used in any installation.

Table 1: Examples of pressure vessel volumes and PE(S)R categories for various refrigerants in a system with an air-cooled condenser at a maximum 32⁰C ambient.

This has been a snapshot of a few of the critical differences that the current regulation and standards require when planning to change to very low GWP options. Planning ahead is key to ensuring there is no disruption when the phasedown in the F-Gas regulation affects the availability of the higher GWP refrigerants and getting up to date with current standards and regulations is essential to ensure compliance is maintained. As always help is at hand with Climalife able to offer advice on refrigerant selection, applicable standards and regulations, tools to make calculations for customers and also training programs to ease the path.