Refrigerant Retrofits

Climalife UK

After the recent Refrigerant Retrofitting webinar, we caught up with UK Head of Sales; Dave Richards for his thoughts on market conditions and retrofit options for businesses ahead of the next major F-Gas step in 2021.

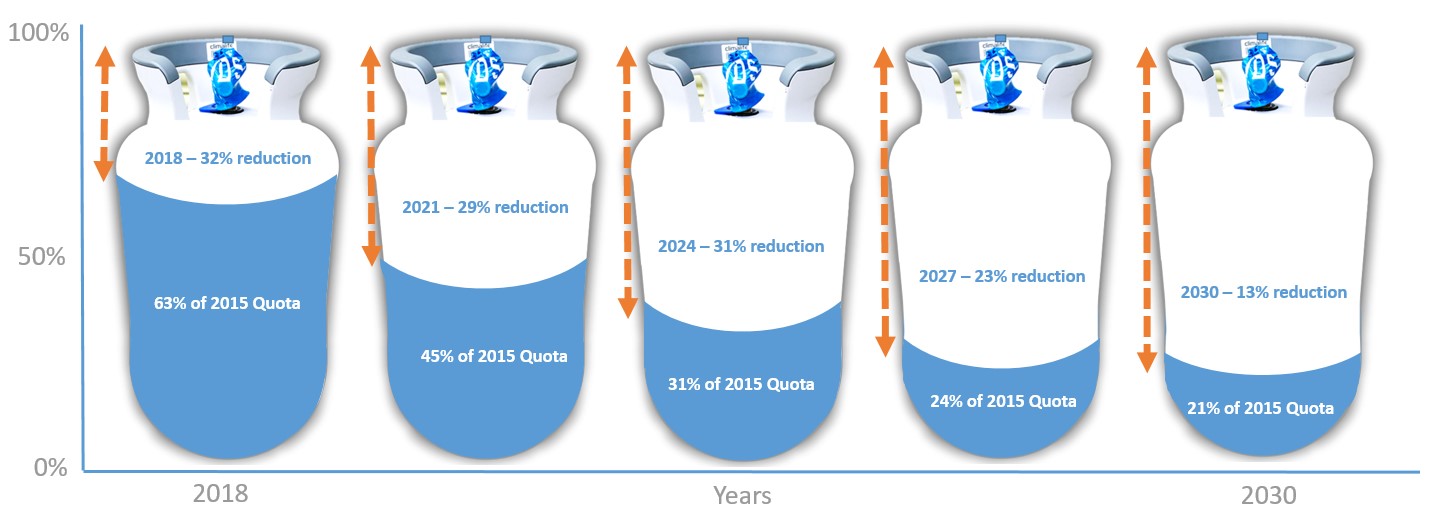

F-Gas has been the main driver of change in our industry since the first legislation came into force in 2006. Since then there have been a number of restrictions and bans on different types of equipment. The most recent ban was in January 2020 in relation to the use of virgin refrigerants with a GWP >2500 in stationary refrigeration systems with a charge over 40 CO2 equivalent tonnes. Whilst there are exemptions, the real barrier is the quota system which will have greater impact on the supply of higher GWP virgin refrigerants. The next F-Gas phase down step is just five months away in 2021 when the quota will be cut by a further 29% compared to this year’s allowance.

F-Gas has been the main driver of change in our industry since the first legislation came into force in 2006. Since then there have been a number of restrictions and bans on different types of equipment. The most recent ban was in January 2020 in relation to the use of virgin refrigerants with a GWP >2500 in stationary refrigeration systems with a charge over 40 CO2 equivalent tonnes. Whilst there are exemptions, the real barrier is the quota system which will have greater impact on the supply of higher GWP virgin refrigerants. The next F-Gas phase down step is just five months away in 2021 when the quota will be cut by a further 29% compared to this year’s allowance.

15 Year F-Gas Phase down plan

There have been external forces relieving some of the pressure on quota recently, illegal product into parts of Europe has had an impact, and this year COVID-19 has temporarily reduced the demand for refrigerant taken from the quota system in some sectors.

The full effects of the quota system were felt in late 2017 and 2018, the last major drop in quota allowance with pricing rapidly increasing and some availability issues. Whether we will see a repeat of this situation in 2021 is difficult to predict, but history tells us of the importance of planning ahead. As for Brexit, there are still some unknowns, but at present it looks like the UK will not be part of the EU quota system but will have its own aligned quota system based on historical supply which will mirror the EU system with a cut in quota availability 2021.

Retrofit Overview and Good Practice

Many people have been retrofitting systems where the refrigerant has a GWP >2500 and we encourage the market to continue change if they are not currently in a position to invest in new equipment that could use very low GWP products.

Improved energy efficiency can often be realised from retrofitting R-404A and R-507 Dx systems to refrigerants such as R-448A and R-449A. In the short term retrofits are significantly cheaper than new equipment options and companies can reduce their CO2 footprint by replacing a high GWP refrigerant with a lower one, if leakage rates can also be reduced at the same time then the CO2 footprint is reduced even further.

What are the retrofit options?

R-404A/R-507A/R-422A dx

With R-404A and R-507 now banned in new equipment, R-448A and R-449A have widely been used in both new equipment and for retrofit. There have been many successful conversions of direct expansion (dx) and capillary systems over the last 5-6 years. Many supermarkets, industrial, light industrial and smaller hermetic systems have successfully been converted.R-448A and R-449A are proven options for most dx systems with usually a nominal adjustment of the expansion valve.

Another solution, R-452A is the closest match to R-404A performance, discharge temperatures and mass flow, but its GWP means it should only be used where R-448A or R-449A cannot. This tends to be transport refrigeration, small hermetic and low temperature applications where the discharge temperature increase cannot be overcome by liquid injection or oil cooling.

Compressor selection software is available on-line and can be used to check suitability.

R-407A and R-407F

R-407A and R-407F have themselves been used in new equipment and as a retrofit for R-404A. The GWP values of 2107 and 1825 respectively mean they are not banned under F-Gas, but quota reductions in 2021 and 2024 may affect them. Both can be replaced by R-448A or R-449A (depending on the age and type of installation).

R-404A/R-507/R-434A/R-428A flooded systems

Flooded systems vary in design and can be gravity fed, pump circulation, and low-pressure receivers (LPR), most are bespoke to a specific application. Therefore, each application needs to be looked at individually. Many are old R-22 systems that are over 30 years old where the only options are to replace with new equipment usually using Ammonia or rely on availability of reclaimed refrigerant. We are aware of a couple of systems that have been successfully converted including an LPR, but there is little or no data available other than they are working.

R-422D & R-434A

With GWPs >2500, R-422D and R-434A were used to convert R-22 Dx systems. If the equipment is not being replaced, the easiest retrofit would be to use either R-438A or R-453A, similar products which were also used to replace R-22. Both allow the same oil type to continue to be used. Another option would be to consider R-448A or R-449A, both would require a full POE oil change and the system pressure rating would need to be checked.

R-134a

R-134a has a relatively low GWP compared to other refrigerants and isn’t banned, but R-513A is now widely approved in new equipment, has less than 50% of the GWP of R-134a and is easy to retrofit with a very close match on COP and capacity. R-450A can also be considered a retrofit option if a system has enough spare capacity.

R-410A

R-410A is not affected by the current legislation for existing equipment, however at 2088 GWP could come under pressure from quota reductions. R-32 is not a retrofit option. New to market is R-470A (RS-53), it has an A1 classification with a GWP around 50% less than R-410A and has a similar cooling capacity and pressures to R-410A but without compressor approvals. There are other products in development, such as HDR-147 from Honeywell but at this time we do not have any further information on technical data or availability.

Reclaimed Refrigerant

Reclaimed refrigerants continue to play an important part in keeping systems with a high GWP operating and will continue to do so for many years. However, they are a finite source, that isn’t available in limitless quantities, as they require existing systems to be retrofitted or replaced.

Looking forward

These are unusual times for all of us. We have the next F-Gas phase down step looming, encouraging us to shift to products that have lower environmental implications as well as maximising the energy efficiency of our cooling systems. But with the recent lockdown, we all seem to be much more aware of these environmental goals that go hand in hand with our daily lives. So we have to consider our options. Do we invest now in new equipment with very Low GWP such as the A2L Refrigerants? There are some good replacement options available, or do we consider retrofitting? The real answer is a mixture of both options, refrigerant suppliers such as Climalife understand these decisions and can give you helpful advice on which is the best route to take for your business and your applications.