Refrigerant Recovery - Why it is important for the transition to low GWP refrigerants

Climalife UK

F-Gas and Quota

The F-Gas Legislation states that all HFC refrigerants from refrigeration and air conditioning systems must be recovered and any reclaimed and recycled refrigerants with a GWP >2500 can continue to be used for a further 10 years after the service ban on virgin product use came into effect on 01/01/2020.

Recovered and reclaimed refrigerant will play a key part in helping the industry to meet the phase downs from the F-Gas Legislation. Reclaimed HFC’s are as such ‘quota free’ so will be crucial in ensuring there is enough product available on the market to satisfy demand as the phase down in quota impacts availability.

The next F-Gas phase down will come in at the start of 2021, this is also aligned with the UK due to have its own quota system in place, making it important that recovery and reclamation of refrigerant continues in order to ease the pressure of availability in this next phase down.

Reclaimed or recycled product can still be used for servicing, but the availability of these high GWP refrigerants is completely dependent on systems being converted or replaced and demand for reclaimed product not exceeding the amount that comes back for re-processing over the next few years.

Refrigerants with a GWP over 2500 include R-404A, R-507A, R-422A, R-422D, R-428A and R-434A. Whilst it is expected that reclaimed R-404A may remain available for some time, some of the other refrigerants may not be as easy to obtain from all suppliers.

Recycle or Reclaim?

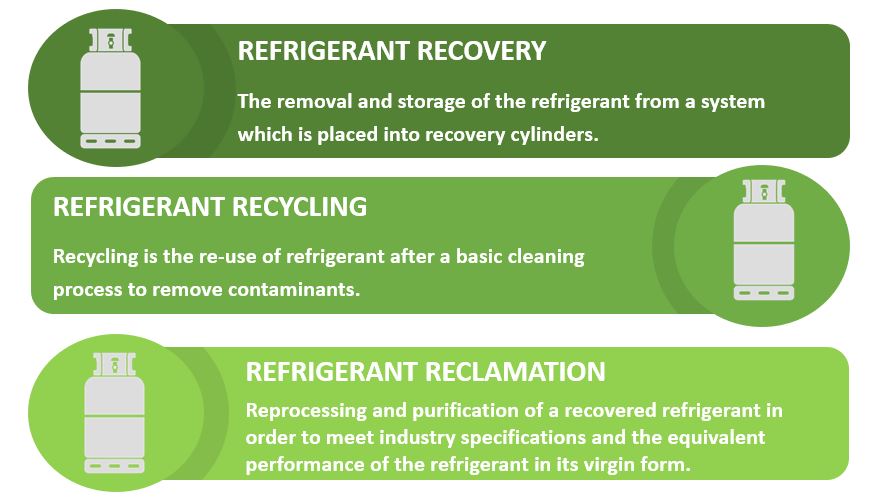

Reclaimed refrigerant is often mistakenly called recycled refrigerant. They sound similar, but in reality, they are vastly different. A correctly reclaimed refrigerant which is normally reprocessed by your supplier of refrigerants, will have the same specification as virgin refrigerant.

As recycling only puts the recovered refrigerant through a basic cleaning process, it usually means there is no analysis or quality assurance attached to the product in terms of specification or purity. If all of the contaminants are not fully removed through the recycling process, then the recycled refrigerant may cause harm if introduced to other systems. If a mixture is returned to a system along with any unremoved contaminants e.g. oil or moisture, it may not perform in the same way as the virgin or reclaimed product and could cause system operation issues and impact system efficiency.

Refrigerant reclamation is a more intense and thorough process that includes analysing the specific contaminants, which can each then be filtered and removed meaning impurities are taken from the refrigerant and it is returned as close to its virgin form as possible.

For best quality, system operation and general peace of mind it is recommended recovered product is bought back to AHRI specification by a professional reclamation process.

The Recovery Process

Recovering refrigerant can be a lengthy procedure and there are various methods that can be utilised to improve the speed of recovery, including the push-pull method where the recovery unit ‘pulls’ vapor from the recovery cylinder and produces high-pressure discharge gas that ‘pushes’ liquid out of the system and back into the recovery cylinder. There are also specialist recovery units which can recover refrigerants quickly from systems with bigger volumes, particularly where the time to recover the refrigerant may be critical and installation shut down time limited.

The Reclamation Process at Climalife UK

At Climalife UK, the recovered refrigerant is returned to the filling plant in Swansea, adhering strictly to the Hazardous waste regulation procedures along with correct documentation, with the site holding a waste licence to reprocess refrigerant. Typically, all recovered refrigerant that is returned can be out of specification for moisture content, acidity and high boiling residue such as particulates.

After initial analysis to confirm product identity it is re-processed by a combination of distillation, cleaning and drying processes back to AHRI 700 specification which has the same conformity as virgin product. This enables the reclaimed refrigerant to be placed on the market as regenerated product and it will perform in the same way as virgin product would.

The F-Gas legislation requires that all cylinders containing reclaimed or recycled product must be labelled as such, have a batch number and identify where it was re-processed to facilitate traceability. All F-Gas records that are kept by a user also need to record that reclaimed product was used and where it came from.

Reclaim and retrofitting

Many Climalife UK customers have found that an easy way of creating reclaimed product is to convert existing systems to an alternative lower GWP refrigerant for example R-448A and R-449A; these being the most popular conversion refrigerants which have proven to be easy to use for those familiar with conversion procedures.

The recovered product is then returned to the Climalife facility for reprocessing for re-use as reclaimed product in other systems that may be less practical to convert.

Climalife ran a useful webinar recently which is available on their YouTube channel, with more detail on the retrofitting and the options available.

A Sustainable Short-Term Solution

There has been a real shift in recent years with more and more people finding ways to improve their business, personal environmental impact and carbon footprint. Therefore, customers are more likely to be considering environmental factors of systems such as energy efficiency, as well as cost factors.

By using reclaimed refrigerant, it is a way of decreasing the carbon footprint because it is reducing the production and supply of virgin refrigerants.

Even though reclaimed refrigerant can be an ideal short-term solution for systems still running on >2500 GWP refrigerants, there are other long-term considerations that need to be made. Using a reclaimed refrigerant may allow time for a decision to be made or capex to be allocated on a retrofit refrigerant or a new installation with a lower GWP refrigerant.

Companies such as Climalife understand the importance of recovery and reclamation within the industry, which is why it has a number of its own solutions to aid in the recovery of refrigerants, including a professional recovery service to facilitate rapid recovery of larger systems.

For more information or technical assistance, Climalife has a team of experts ready to help.

We care for our customers, people, products and planet.