Are you ready for A2L refrigerants?

Climalife UK

Peter Dinnage looks at where we are with the uptake of A2L refrigerants.

We are five years into a 15 year phase down of HFCs that started in 2015. By 2030 the current F-Gas Legislation requires the market to have reduced the CO2 equivalent tonnes being placed on the market by 79%. To meet the phase down timetable the move to even lower GWP needs to quicken and will require the use of A2L refrigerants in greater quantities.

The market is changing, with the high GWP refrigerants R-404A and R-507 now banned in most applications. The very low GWP refrigerants need to be used in new equipment now entering the market, and with the next phase step coming in 2021, the uptake in A2L refrigerants should start to gather pace.

What are A2L refrigerants?

The term A2L refers to a safety classification based on ISO 817 and ASHRAE Standard 34 for toxicity and flammability. Toxicity is divided into two categories, A for lower toxicity, B for higher toxicity, whilst flammability is divided into four groups; 1, 2L, 2 and 3; assigned depending on several flammability parameters including Lower flammability Limit (LFL), Heat of Combustion and Burning Velocity. 1 is non-flammable, 2 is flammable, 3 is higher flammability, whilst the 2L category is often referred to as mildly flammable and has a requirement that the burning velocity must be 10cm/sec or below. For example R-32 has burning velocity 6.1 cm/sec and R-1234yf 1.5 cm/sec.

Wheret are A2L refrigerants being used?

R-32, R-1234yf and R-1234ze are the most commonly used A2L refrigerants on the market at the moment, but blends containing these refrigerants are also finding favour in a growing number of very low GWP applications. All new cars produced for the European market have been on R-1234yf since the beginning of 2017. Whilst it is reported that 37% of the European market for split system AC is on R-32 and it is expected to exceed 80% in 3 years. In last two years it is also claimed that 70% of all new split AC in the UK are being installed on R-32. Manufacturers are also bringing to market some VRF systems on R-32, whilst chillers are available with 1234ze. The transition to lower GWP and A2L refrigerants is under way and legislation will require even greater uptake of lower flammable A2L refrigerants as the HFC phase down towards 2030 progresses which each cut in quota.

Compressor manufacturers and equipment builder are now more comfortable with A2L refrigerants as they roll out approvals and we have seen the use of A2L refrigerants in supermarket applications, cold storage and food production areas.

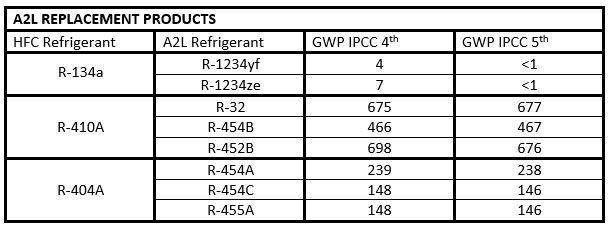

In Table 1 is a list by application of A2L refrigerants along with their properties.

Table 1

What is holding back the use of A2Ls?

By their very nature they are not retrofit options but for new equipment, therefore the speed at which they come to market is much slower, as compressor and equipment manufacturers test and approve their use. These approvals are now coming through and their use is expected to grow significantly.

The roll out has been slow because engineers need to be trained to safely work with and understand how to handle flammable refrigerants. Like other new refrigerants in the past, initial concerns are soon overcome as experience and knowledge is gained. There is plenty of guidance from trade bodies on handling flammable refrigerants and the additional risk assessment required. The use of such refrigerants is also covered by standards, which are again shown in Table 1.

EN378 was updated in 2016 to include A2L refrigerants and provides guidance on charge size requirements for different locations and application areas, along with what can be achieve with additional mitigating circumstances that will allow the safe use of larger charge sizes

Refrigerant training

Anyone working with refrigerants, whether they are HFCs, HFOs, CO2, Ammonia, or Hydrocarbons must be properly trained in their safe handling and have knowledge of their characteristics; whether it be pressure, toxicity or flammability. Engineers who only have experience with non-flammable refrigerants need to be trained in the additional considerations for their own safety. Most of it is common sense and best practice to enable them to work safely and avoid ignition sources where they are working.

Risk Assessment

Anyone handling current refrigerants should have carried out and documented a risk assessment on their use and this is no different for flammable refrigerants as the additional risk need to be considered and actions required. Those who handle Ammonia will already be familiar with the requirements. Again guidance on DSEAR and risk assessment is available from Government websites and trade associations. When handling any refrigerant the associated risk will vary dependent on the refrigerant and its properties and will be different for equipment manufacturer, installers, and service companies.

Each refrigerant has different properties that need to be considered such as Lower and Upper Flammability Limits (LFLs and UFLs), Minimum Ignition Energy (MIE) and burning velocity, so that risks can be fully evaluated and avoided in potential leak scenarios.

What are the benefits of A2L refrigerants?

One of the benefits of the A2L refrigerants blends is that they have been formulated to be able to be used in many of the same applications as current HFC refrigerants and give very similar performance characteristics. Coupled with their lower flammability levels they are relatively easy to adapt to. As experience of these new fluids is growing there are a number of studies that are being published that show that these new A2L refrigerants are also more energy efficient than the other Low GWP technologies. With refrigeration and air conditioning equipment attributed to consuming 17% of total electricity demand, energy efficiency is going to be a key topic in the climate change debate as we move to a carbon neutral position.

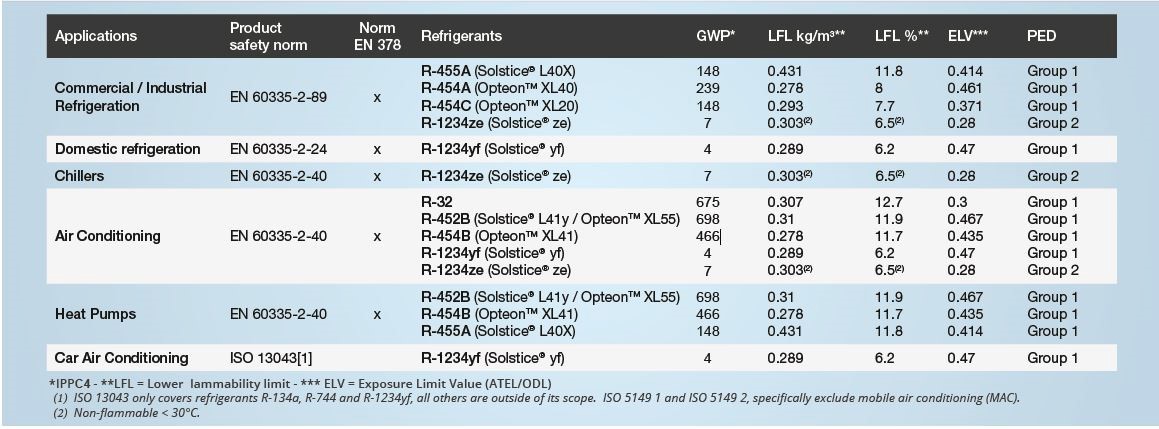

Current A2L refrigerants that are readily available are listed in Table 2.

Table 2

The next Quota cut is less than 12 months away and with the UK operating its own UK F-Gas quota system from 2021, this could have a greater impact on the higher GWP refrigerants in 2021, with price and availability being inextricably linked. We all want to avoid what happened in late 2017 and early 2018, therefore A2L refrigerants will have a very big part to play as a solution to meeting these legislation goals.

Would you like to find out more about A2L options for an upcoming project? Why not call us today on 0117 980 2520.

View our Good Practice Guide to A2L Refrigerants here.