Leak Detection: The part it will play in the UK 2050 net zero target

Climalife UK

Climalife UK Head of Sales, Dave Richards, looks at the importance of leak detection and the part it will play in achieving the UK 2050 net zero target.

F-Gas regulations plan for a 79% decrease in total CO2 equivalents (tCO2e) for HFCs placed on the market by 2030, with a further small reduction to achieve the Kigali Amendment goal for 2036. The overall aim is to reduce and contain refrigerant emissions by taking every step to adopt responsible refrigeration practises.

A leaking system costs money and will go on costing money until the leak is fixed. Not only do fixed leak detectors ensure a leak is identified quickly it also helps the equipment owner remain legally compliant with F-Gas legislation.

Leak detection and prompt action following a leak being detected, can help to maintain the optimum efficiency of a system; avoiding an increase in energy consumption, reducing the amount of refrigerant lost to the environment and the amount needed for topping up a system to the correct level.

Reducing emissions of global warming gases is a key aim of the F-Gas legislation. The requirement for leak detection, inspection and leak check frequency depends on the total CO2 equivalent tonnes (tCO2e) charge of the equipment. It is mandatory under the F-Gas regulation (EU517/2014), for systems with a refrigerant charge of 500 tCO2e or more to be equipped with fixed leak detectors. F-Gas compliance also requires regular refrigerant leak checks and immediate repairs should any leaks be found.

In addition to industry specific legislation, the UK Government is looking for net zero carbon emissions by 2050 and managing refrigerant usage and minimising leaks is a key aspect to the industry playing their part to achieve this target.

How many kg of refrigerant is 500 tCO2e ?

|

Refrigerant |

GWP |

kg = 500 tCO2e |

Refrigerant |

GWP |

kg = 500 tCO2e |

|

|

R-134a |

1430 |

350 |

R-448A |

1387 |

360 |

|

|

R-404A |

3922 |

127 |

R-449A |

1397 |

358 |

|

|

R-407A |

2107 |

237 |

R-450A |

605 |

827 |

|

|

R-407C |

1774 |

282 |

R-452A |

2140 |

234 |

|

|

R-407F |

1825 |

274 |

R-507A |

3985 |

125 |

|

|

R-410A |

2088 |

240 |

R-513A |

631 |

792 |

Owners and operators of the system have the overall responsibility for the legislation and therefore they are responsible for:

- Preventing refrigerant leakage

- Ensuring that leak checks are carried out

- Repairing any leaks as soon as possible

- Arranging proper refrigerant recovery

- Maintaining records of any refrigerant losses, additions and servicing

Detect leaks early to reduce refrigerant loss

When it comes to F-Gas compliance, being able to detect a refrigerant leak early, means that the leak can be fixed as swiftly as possible. This also means that the leak is unable to grow into a large-scale leak event and the equipment can continue operating with little to no downtime. From a financial perspective, the cost to replace the lost refrigerant is greatly reduced by early leak detection, this also minimises any potential damage to the environment.

With some refrigerant costs starting to rise again this year and many systems holding thousands of pounds of refrigerant, it is easy to see why an early warning leak detection system is such a good idea as it can detect a leak much more quickly allowing early rectification of the problem and ultimately save money.

It is claimed that a simple leak detection system can save over half of potentially lost refrigerant from a system. There are leak detection products that can suit most types of installation and budgets. Companies such as Climalife who supply Bacharach leak detection products can help and advise on which device is suitable for a particular system. It is very important to ensure the right leak detection equipment is selected, the leak detection needs to be able to withstand heavy usage and keep up to date with changes in refrigerant technologies.

Manufacturers of leak detection equipment, such as Bacharach, are keeping a close eye on changes in the market and offer products that can detect both existing and commonly used refrigerants as well as the newer refrigerants coming to market.

Leak detection equipment may seem like an unwanted expense initially, especially when budgets are tight, however any refrigerant leaks that are detected and resolved sooner rather than later will have financial benefits that should more than offset the initial equipment outlay. It is also important to consider that when any refrigerant prices rise, the cost of resolving any leaks will increase too.

The impact of refrigerant leaks are:

- The environmental impact

- The cost of replacing lost refrigerant

- Safety compliance

- The cost of product or service loss

- Increased energy consumption

It’s important to remember that one of the biggest F-Gas objectives was about reducing F-Gas usage and preventing leaks. This continues to be an essential part of the process and there are some good tools available to help identify leaks before they become a costly problem.

Low-level refrigerant leak detection

As previously mentioned, detecting refrigerant leaks as early as possible will minimise refrigerant loss and reduce operational risks. However, finding leaks especially low-level leaks that can accumulate over time can often be difficult as they can be hard to locate. There are several factors that can influence this such as air flow, refrigerant density, installed equipment location, the type and nature of refrigerant equipment.

Air flow and refrigerant density

Low-level refrigerant leaks often go undetected over time and are only identified when the refrigeration equipment fails through a loss in refrigerant charge. If the low-level refrigerant leak was situated in a sealed area such as a walk-in freezer or cold store, the refrigerant would build up over time and cause an alarm notification. In a similar way, a higher-level leak that is diluted in large volumes of air or is acted on by air flow, will often go undetected at low-levels.

Minimum Detectable Level

In general, an aspirated infrared fixed leak detection system is most effective for detecting low-levels of refrigerant leaks. Aspirated systems provide monitoring with the lowest comparable Minimum Detectable Level (MDL) and provide the highest level of accuracy down to 1 ppm. An aspirated system is cost effective for monitoring larger areas, as the system draws samples from different locations around the site to a single gas detection unit. What’s more, aspirated systems can be connected to automated alarm and notification systems so even low-level leaks can be addressed quickly and effectively.

Leak detection: The solutions available

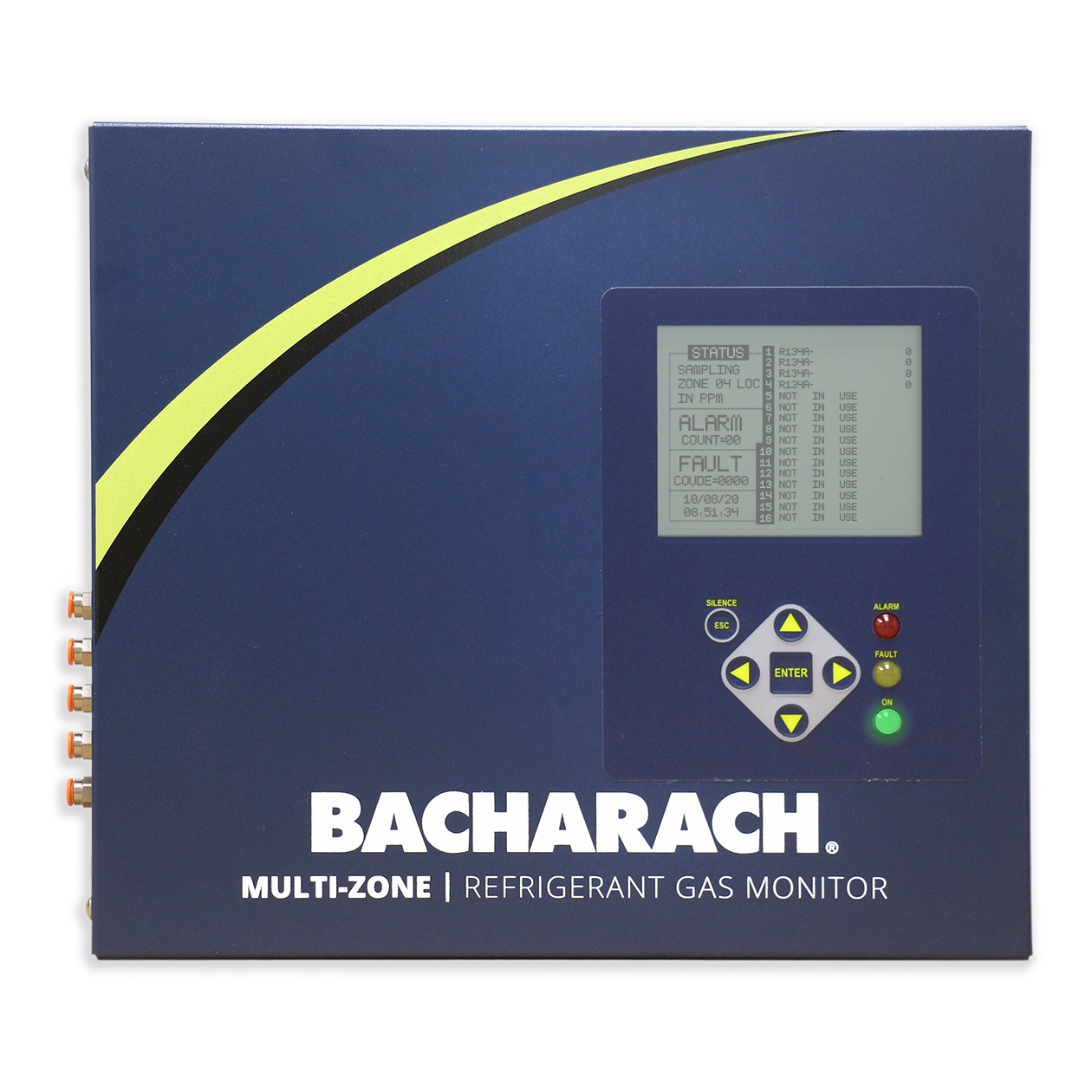

Bacharach provide a number of low-level refrigerant monitoring solutions for F-Gas compliance. The Multi-Zone and Single-Zone fixed refrigerant monitors and the PGM-IR portable refrigerant monitor.

The Multi-Zone enhances effective refrigerant management, detecting leaks early to  enable cost savings by reducing refrigerant recharge, enhancing energy efficiency and reducing risk of refrigeration failure and produce loss. A variety of communication interfaces are available, including Modbus, BACnet and LonWorks, allowing easy integration into BMS / BAS systems and remote monitoring solutions.

enable cost savings by reducing refrigerant recharge, enhancing energy efficiency and reducing risk of refrigeration failure and produce loss. A variety of communication interfaces are available, including Modbus, BACnet and LonWorks, allowing easy integration into BMS / BAS systems and remote monitoring solutions.

It is ideal for:

- Chillers

- Grocery Stores,

- Mechanical Rooms

- Physical Plants

- Refrigeration Racks

- Walk-In Freezers

The MGS-400 Series is a complete leak detection solution, designed specifically for safety compliance in refrigeration applications. Modern refrigeration systems are designed to be efficient and leak free, but improper installation, inadvertent damage or mechanical wear can result in potentially hazardous leaks.

With their rapid response time, low-temperature performance (-40° C) and integrated audio & visual alarms, MGS-400 Series gas detectors make compliance with safety regulations simple and easy.

It is ideal for:

- Machinery rooms

- Walk-in freezers

- Cold rooms

- Industrial cold storage

- Chiller rooms

There are many different factors in our industry that will help influence the success of the UK 2050 Net Zero target and it is important that every one of those factors, which includes leak detection, is considered when installing and maintaining a system. Collectively as an industry, we must do all we can to play our part in finding ways to meet this target and to continue to meet the F-Gas phase down steps.

Selecting the best solution for your business or application may seem daunting but the expert team at Climalife in the UK, working in partnership with Bacharach, can advise you on leak detection solutions by providing tailored guidance on the location of equipment, type and number of sensors to use, setting you on the journey to achieving environmental excellence and saving money by stopping refrigerant leakage and maintaining optimum energy efficiency.

We care for our customers, people, products and planet.