Largest single circuit chill store installation in the UK using very low GWP R-454C refrigerant

Climalife UK

Many small to moderate size chill stores have traditionally operated using relatively high GWP (>1000 GWP) refrigerants, due to this technology being the most cost-effective option, but with the F-Gas regulation phasedown encouraging users to move to using much lower GWP options, a change in refrigerant strategy is needed. When EJM Engineered Systems were presented with the challenge of offering a very low GWP option for a 15,000m³ medium temperature cold room for food storage, they contacted Climalife to discuss the refrigerant options available.

EJM are very experienced in chill store refrigeration but the typical option of R-448A or R-449A was quite rightly not considered low enough GWP to be sustainable. A store of this size posed a challenge in finding a cost and energy efficient solution with a sufficiently low GWP to be considered sustainable for the expected lifetime of the equipment. Together EJM and Climalife were able to combine their areas of expertise to propose a very low GWP solution that was both cost and energy efficient.

Considering energy efficiency and energy consumption

The options available to EJM were R-290 or R-717 with a secondary heat transfer fluid loop, a R-744 direct expansion system or a R-454C direct expansion system. Many chill store applications have been installed using either the R-290, R-717 or R-744, but none of this size have previously been installed using this type of refrigerant in a single circuit direct expansion system

By working together, EJM and Climalife were able to combine their engineering expertise and refrigerant knowledge to assess the various technology options for refrigeration system performance, standards and legislation compliance.

All options will of course provide the required cooling for the application, but theoretical performance calculations performed by Climalife, cross referenced with manufacturers published system data for the various options, revealed that R-454C delivered more than 20% higher energy efficiency compared to R-744 and equivalent or lower energy consumption than the combined power from a R-290 or R-717 system with pumped secondary heat transfer fluid loop.

Paul Cable (EJM Managing Director) commented “EJM have a great deal of experience installing industrial systems using higher risk refrigerants such as R-744, R-717 and R-290 but using an A2L refrigerant was new for us. The knowledge and expertise provided by Climalife allowed us to proceed with confidence and deliver the innovative very low GWP solution the customer wanted “.

System designs and costing

System designs and costings performed by EJM demonstrated that although it would be possible to follow the methodology employed in other projects and use energy inefficient R-744, or multiple refrigerant circuits with much lower refrigerant charges to achieve the desired cooling, this would greatly reduce the cost advantage of a single circuit system and would also erode some of the energy efficiency advantage.

Comparisons vs CO2 and multiple systems utilising other refrigerants and secondary cooling circuits would see a circa 28% – 32% increase in cost due to capital plant, labour and materials along with multi power supplies. Footprint space for the refrigeration equipment was also a limiting factor and the single system approach added this additional benefit.

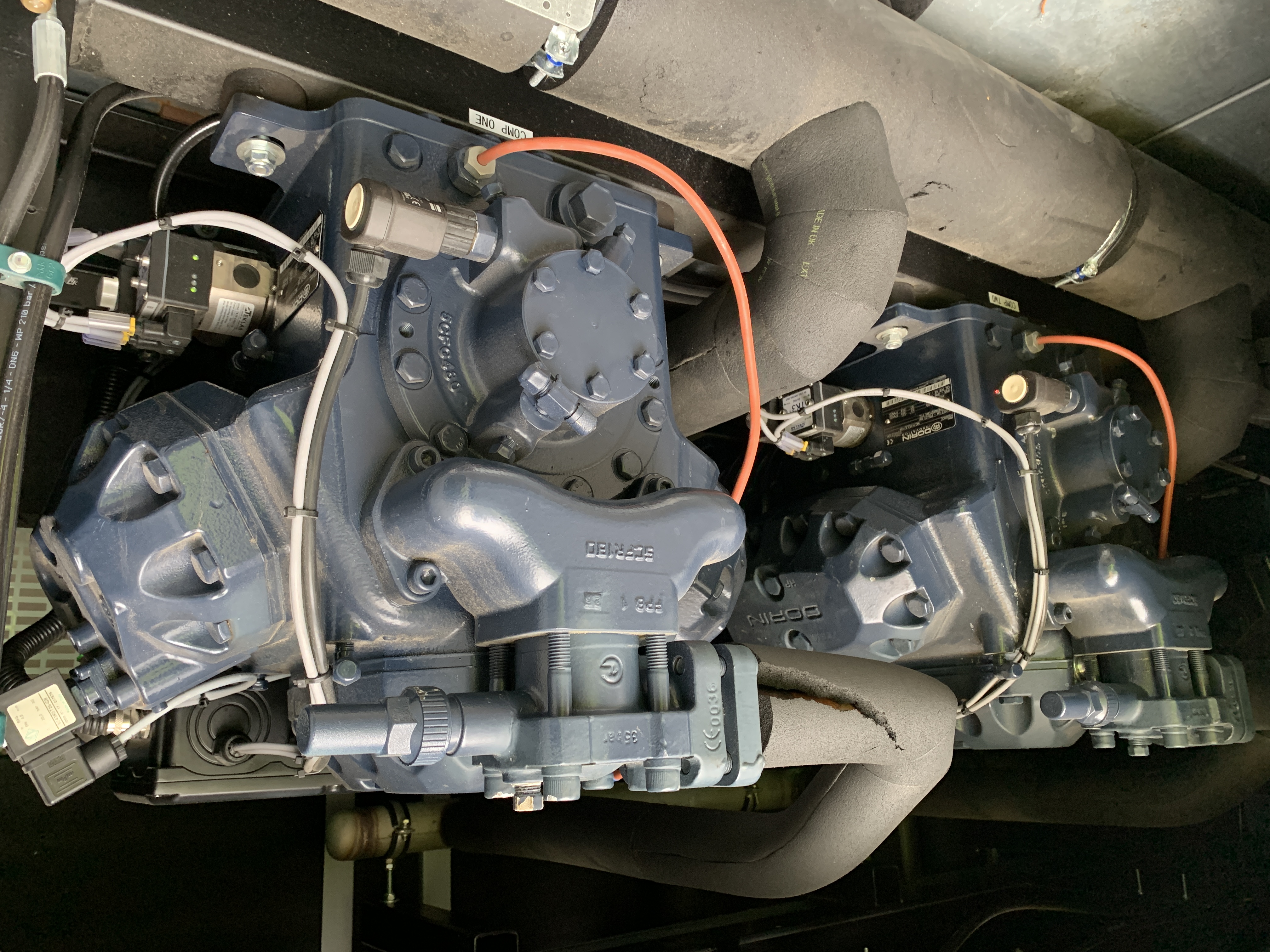

The challenge for implementing R-454C was that the system would need approximately 400kg of refrigerant. This quantity is far greater than the maximum charge size specified within EN 378 for an occupied space (57kg for R-454C), plus R-454C falls into the higher risk fluid group 1 under the pressure equipment safety regulation (PE(S)R).

To the best of the knowledge of all the participants and the refrigerant manufacturer, this is the biggest single circuit chill store installation in the UK using a refrigerant of the same safety classification and an innovation that could easily be repeated in many other future installations, offering a cost effective, environmentally sustainable and energy efficient solution in the drive towards very low GWP refrigerant adoption.

Working together using their combined knowledge of standards and regulations, EJM and Climalife determined that within EN 378 there is a derogation for applications where there is <1 person per 10m2 , which does not limit the refrigerant charge quantity. This derogation does not mean that no further protective measures are required and with reference to EN 378 it was recommended that gas detection was placed at any potential leakage location, automatic shut-off valves were installed to each item of plant within the chill store isolating each component to maintain safe limits within the enclosed space if a leak was detected, and audio and visual alarms, again linked to the gas detection system. Although the compressor enclosure was external to the chill store, additional ventilation, linked to gas detection, was installed to ensure no hazardous zones were created.

It is important to note that a system using a similar refrigerant charge of R-448A/R-449A, under the F-Gas regulation, would also require fixed gas detection to be installed.

Neil Roberts (Climalife Senior Technical Sales Manager) added “It can be difficult to keep up to date with the latest refrigerants, latest legislation and how standards apply to the new refrigerants, so it’s important that we stay informed and are able to advise our customers on the best options and what needs to be done to ensure compliance. Working with EJM was a perfect combination. Climalife were able to advise EJM on the best performing options and how to use them within current standards and legislation and EJM had all the knowledge and expertise to make it a reality, providing the customer with a cost and energy efficient sustainable very low GWP solution.“

20% lower energy consumption than an equivalent R-744 system

The system was commissioned in October 2022 and has not had sufficient operating time to perform a detailed energy analysis however, based on the design conditions and the theoretical performance calculations the energy consumption is expected to be at least 20% lower than an equivalent R-744 system with total annual emissions at least 17% lower, assuming a 5% per annum refrigerant leakage rate (should be much lower due to extensive gas detection) and using electricity CO2 conversion factors published by the Department for Energy Security and Net Zero (formerly BEIS).