Is your refrigerant strategy still fit for purpose?

Climalife UK

Neil Roberts of Climalife discusses

I guess the first question should really be "do you have refrigerant strategy?" If the answer is “no”, you are probably wondering why you need one now. Having previously successfully navigated the changes from either CFCs, HCFCs or the more recent move from high GWP HFCs like R-404A to lower GWP refrigerants such as R-448A or R-449A, you are probably thinking the next phase of the transition to lower GWP will be just as straight forward, but that may be a big mistake. The refrigerant landscape is about to change again, but this time it is going to be different, this time there will not be long term retrofit options that will allow an easy transition. A plan on how to get from where you are today with refrigerant usage to where you need to be to comply with legislation will be crucial to avoid unpleasant surprises and potentially could save a lot of unnecessary cost.

Why is the change different this time around?

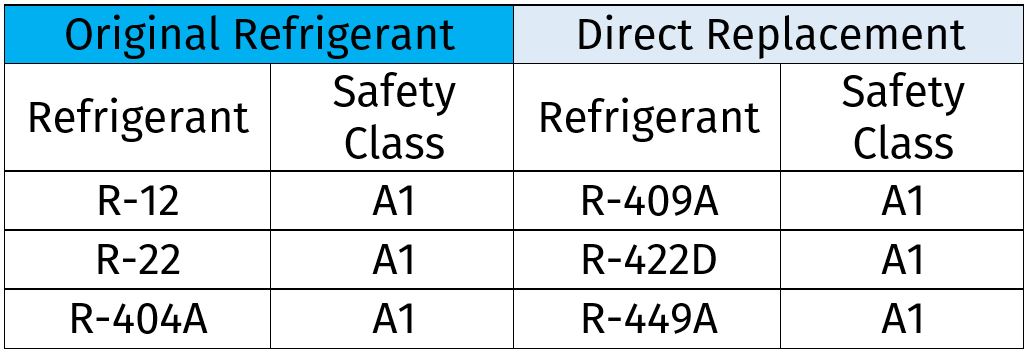

Until now every time legislation has restricted the use of certain refrigerants, a range of direct replacement products have been available to replace the old refrigerant whilst maintaining the use of the same equipment with no or minimal hardware changes. This was possible because the replacement refrigerants had similar performance, similar physical properties and had the same safety classification as the product being replaced (table 1).

Table 1 - Examples of previously available retrofit options

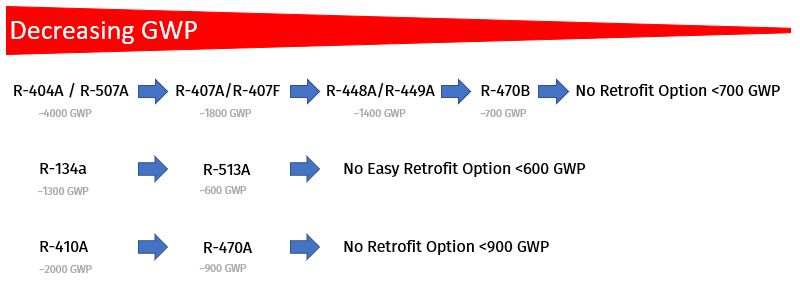

The phasedown in the current F-Gas legislation means the GWP of the next round of potential replacements needs to be at a level where the only products available either have significantly different performance characteristics, significantly different physical properties or a different safety classification making a retrofit at best very difficult and in most cases completely impractical.

Figure 1 - There are no very low GWP retrofit options, in most cases new equipment will be needed to use very low GWP refrigerants

Hence the need for a refrigerant replacement strategy, as using a low or very low GWP refrigerant will require forward planning, and the foresight to identify when, where and how the new approach will need to be implemented.

The same but different!

Fundamentally the requirements for using the new low GWP refrigerants are no different than using the previous and current A1 safety class refrigerants but if the equipment has not been designed for use with the low GWP options it is unlikely to be suitable or compliant with standards and legislation.

Refrigerant charge size

Even before the current range of low GWP refrigerants were introduced EN 378 has given guidance on refrigerant charge size limitations. All refrigerants have a maximum charge size allowance either based on toxicity or flammability.

EN 378 compliant charge sizes (without additional protective measures) for the low GWP options are often significantly lower than for the previously used higher GWP refrigerants. This is likely to require a change in the design of the system. Designing new equipment with smaller charge sizes or using modular systems rather than larger centralised systems are all considerations to be incorporated into the new refrigeration strategy.

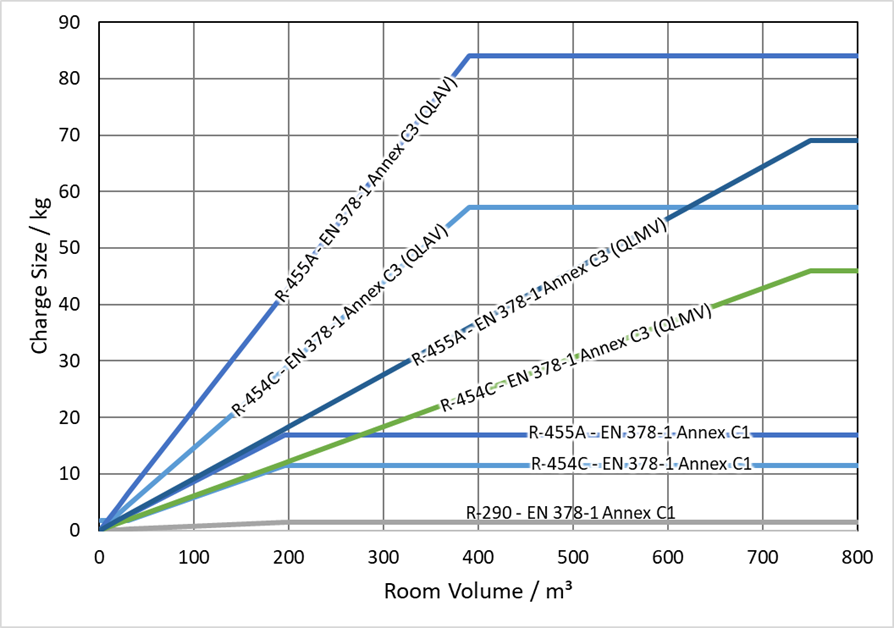

This article will not go into the details of EN 378 but as can be seen in figure 2, in applications using remote condensing units and additional protective measures as detailed in EN 378, relatively large maximum charge sizes up to a charge size of 84kg can be used. This opens up the opportunity to consider A2L refrigerants for many applications where a remote condensing unit is used, the compliant charge sizes for A3 refrigerants are insufficient and the cost or energy efficiency of a R-744 unit is prohibitive.

Figure 2 - Maximum charge sizes compliant with EN 378 including additional protective measures

Dangerous Substsnces and Explosive Atmosphere Regulation (DSEAR) Risk Assessment

A DSEAR risk assessment has been a requirement for all refrigeration systems, even those using non-flammable refrigerants, since 2015. When using a flammable refrigerant, compliance with EN 378 ensures there is a very low risk of forming a flammable atmosphere and therefore beyond showing compliance with EN 378, there are no additional requirements compared to using an A1 safety class refrigerant.

Pressure Equipment Safety Regulation (PE(S)R)

As with EN378 and DSEAR, PE(S)R applies to all refrigeration systems with a PS above 0.5 bar. The fluid group of the low GWP refrigerants which have flammability limits at 20°C is fluid group 1 as opposed to fluid group 2 for the non-flammable refrigerants at 20°C. In some cases, especially when using the higher-pressure flammable refrigerants, the system will be rated in a higher compliance category (see table 2) but the requirements for each category are the same irrelevant of the refrigerant.

Table 2 - Examples of PE(S)R categories for a pressure vessel on the high-pressure side with different refrigerants

Minimising the size of pressure vessels or removing completely may limit the impact of the change in refrigerant. Where systems are rated as Cat II or higher it is necessary to involve a notified body and for any piping designated as Cat II or higher a notified body approved brazing qualification will also be required.

The data in table 2 clearly shows all the high pressure or flammable low GWP options will move into higher PE(S)R categories at much lower vessel volumes than the previous higher GWP refrigerants and this is the main reason why in many cases it will be impractical to use these products as retrofit options.

So, what is the strategy?

Whilst availability of moderate to high GWP refrigerants is still good, it is easy to be lulled into the false sense of security that the time to change is somewhere in the future, but already systems being installed today run a very high risk of not fulfilling their expected lifetime due to the choice of an unsustainable refrigerant.

Low GWP refrigerants are readily available, and the availability of suitable equipment is rapidly increasing meaning there is no reason why a sustainable low GWP options cannot be installed today. In many cases improved energy efficiency can be achieved lowering operating costs as well as reducing emissions for the expected lifetime of the equipment.

It may all seem very daunting changing to something new but the team at Climalife have the expertise to help guide you to a more sustainable refrigeration strategy.

It is human nature to try to avoid change but this one is inevitable so while there’s still time, why not get ahead of the legislative curve and steal a march on your competition.

R.JPG)