Groundbreaking cold store installations using 824kg of Low GWP Opteon™ Refrigerants

Climalife UK

SK Refrigeration Heating and Cooling in collaboration with Chemours UK Ltd.

Introduction

It can never be said that the RACHP industry is dull. With a constant stream of opportunities and challenges presenting themselves in the form of energy saving requirements and environmental concerns, there is a lot for us to do and to look forward to.

The good news is there are refrigerant solutions available that can help us contribute to governments’ drive towards net zero as well as offer benefits to both our own businesses and those of our customers.

Many of these solutions are Low or Very Low GWP HFO blends. These refrigerants are essential if we are to provide flexibility and a variety of options for the future. They also benefit from being energy efficient in terms of absorbed power and are therefore often the best choice when considering both direct (leakage) and indirect emissions (CO2 Emissions per kWh of electricity generated). Energy costs and security have also been high on the news agenda and have further increased the need to be efficient. If photovoltaic panels are the preferred power source, then an efficient system will also limit the number of panels required and therefore additional CapEx.

The majority of these Low GWP HFO blends have the safety class A2L. It’s not that long ago when discussions centred on how to use these mildly flammable refrigerants safely and compliantly with standards (EN 378 – EN 60335) and perhaps more importantly, regulations (PED / PE(S)R). Charge sizes and risk assessment (DSEAR) raised concerns due to the A2L classification, although it is often overlooked that this is a legal requirement for all installations and refrigerants including A1’s A3’s B2L’s etc.

Suitable equipment was also scarce as manufacturers took time to assess the potential business value of utilising these fluids. Thankfully, the necessity for these refrigerants was recognised and appropriate components are readily available today.

Project

In 2021, due to a rapid expansion of their business, Nationwide Foods Ltd in Evesham required an extension to their existing storage facility. The design needed to provide cooling to multiple spaces at various temperatures depending on the requirements of the fruit and vegetables stored. This extension also enabled the redevelopment of pre-existing stores into a marshalling / packing area for goods inward and out.

The projects are known as “5 chambers” and “Marshalling”, have a combined volume of 25,400m³ and are served by 14 systems using a total of 824kg of Opteon™ XL40 (R-454A).

A variety of common solutions were contemplated to suit their business model with factors such as the available PV capacity allowed under planning permissions, budget and past experiences with centralised refrigerated plant all being considered.

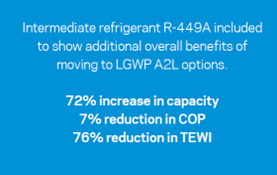

Initially the design centred on R-448A, mainly because this is an A1 refrigerant. However, the client wanted to futureproof against rising refrigerant costs resulting from F-Gas quota restrictions, and with a GWP of 1386 (AR4) this refrigerant was ruled out. They also wanted to select the lowest available GWP that would enhance their environmental credentials and be sustainable for the long term.

After careful consideration, multiple circuits charged with Opteon™ XL40 with a GWP of 239 (AR4) were chosen. These offered significant savings in terms of CapEx and OpEx when compared to centralised plant using CO2 or NH3 , with an additional benefit of built-in redundancy ensuring product safety and quality in the event of a loss in refrigerant charge during times of high ambient temperatures.

The use of an A2L refrigerant did require some thought in terms of risk assessment, particularly as the design called for such a large charge size on site. Fortunately for this particular project there were no limits to charge size due to large room volumes, equipment location and class of occupancy. (EN 378-3 location Cat II, access Cat C and <1 person per 10m²).

5 Chambers Details

Totalling 1700m3 split between 5 rooms 5 chambers was phase 1 of the refurbishment project

The result is a truly groundbreaking installation by SK Heating and Cooling Ltd (part of the MECSIA group) of Gloucester, and one that has led to a multimillion-pound business segment and a very healthy forward order book for both medium and low temperature storage in the food sector.

The pipe run is in the ceiling void; the internal volume of which is sufficient to prevent reaching lower flammability limit, and ventilation to fresh air provided at both ends of the space. Additional safety measures were incorporated by installing leak detection at the valve station. Visual alarms fitted at each evaporator and audible alarm in each room.

As a new installation there wasn’t an opportunity to make a realistic comparison between performance old and new. However, we did make some comparisons based on operating conditions, refrigerant characteristics and volumetric and isentropic efficiency of the compressors used.

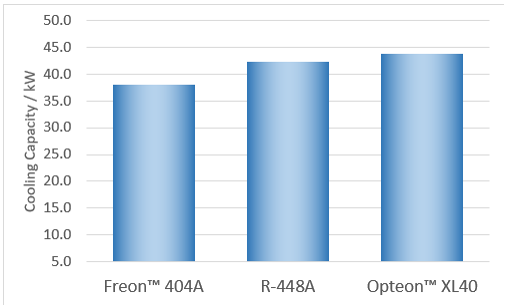

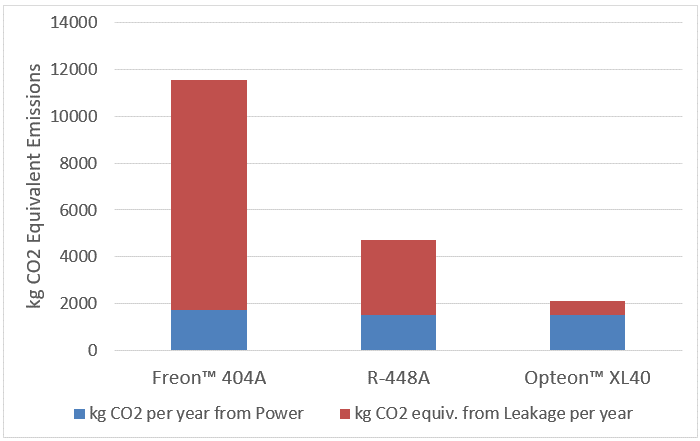

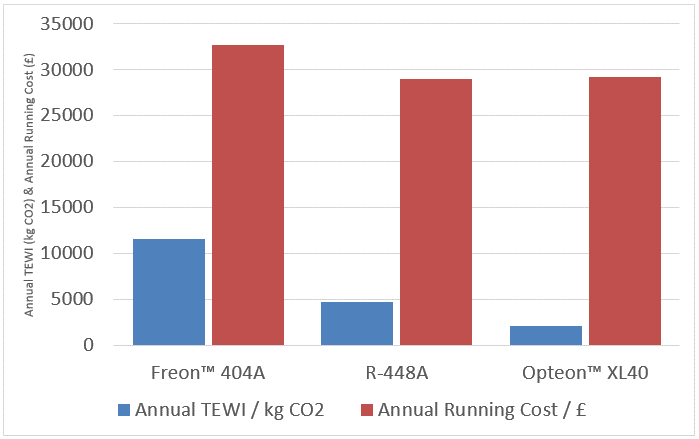

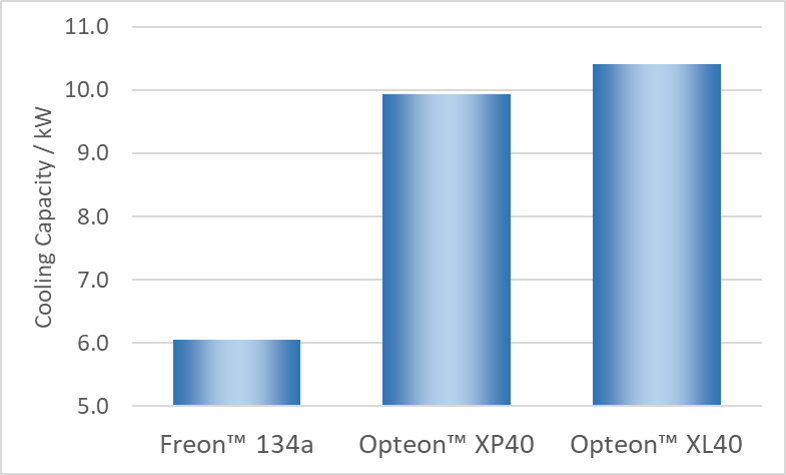

By using Opteon™ XL40 improvement can be seen when compared to the alternatives considered.

Marshalling Area

The new installation completed July 2023 is shown to the left and the legacy system to the right, consisting of two Grasso compressor sets running on R-134a. The old evaporators were installed over the loading docks and required frequent. cleaning due to lorry exhaust fumes. The new instal has dual discharge evaporators located along the centre axis of the room supplied from 3 semi hermetic condensing units.

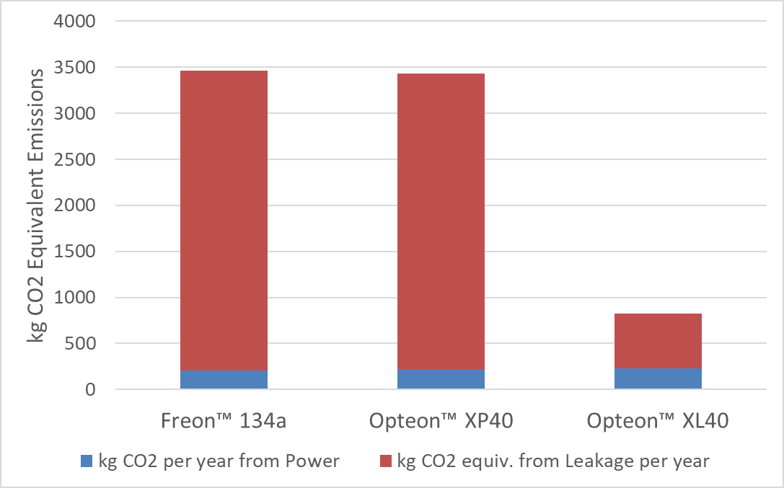

As predicted, significant improvements can be made when moving from R-134a to R-454A. Most significantly the reduction in compressor displacement required. The legacy units having a displacement of 844m3/hr with the new having a total of 234m3/hr.

Conclusions

Low GWP A2L refrigerants have been proven to be a good, safe alternative to use in Cold Storage applications, offering benefits in terms of efficiency and environmental credentials. They provide an excellent alternative option for customers who prefer to avoid centralised plant, thereby providing an additional offering to contractors. No additional skill sets are required of the service engineer when using low GWP Opteon™ refrigerants as system architecture and equipment are familiar.

In comparison to the situation when A2L refrigerants were first being tested, a lot of progress has been made. It is clear that low GWP HFO blends can now be seen as a routine solution for a variety of applications including the cold storage sector where cost and product security are major concerns.

This case study shows we now have readily available low GWP HFO technology to roll out rapidly and at scale when we face the inevitable consequences of reduction in quota in the near future.