TECHNICAL TERMS: What is temperature glide?

When a single component or azeotropic mixture boils at constant pressure, the liquid temperature at the inception of boiling (bubble point) is the same as the temperature of the last drop of liquid as it turns to vapour (dew point) at the end of the boiling process. For these types of fluids, the composition of the liquid and vapour are also the same throughout the boiling process.

In RACHP this process is normally referred to as evaporation. With single components or azeotropic mixtures the temperature difference from beginning to end of the change from liquid to vapour is 0, i.e. there is no temperature glide.

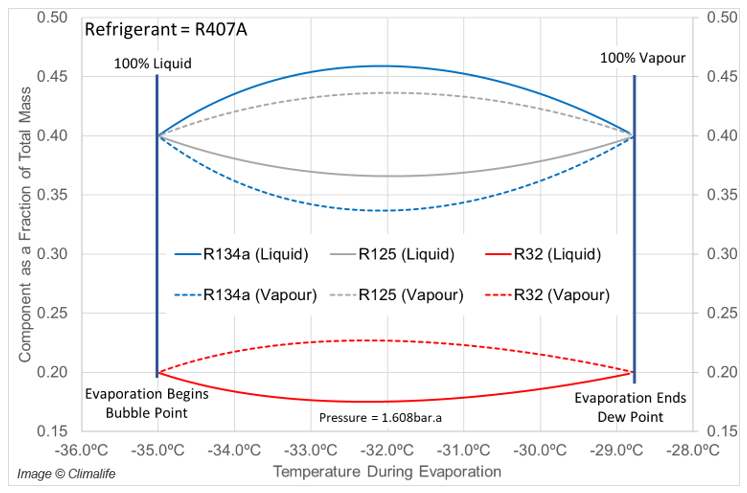

When a non-azeotropic mixture (all R-4XX refrigerants are non-azeotropic) boils (evaporates) there is a rise in temperature between the bubble point and the dew point and this change in temperature is called the temperature glide.

The temperature change is due to a composition difference between liquid and vapour phases during the boiling process causing the boiling point of the liquid phase to rise. It is important to note that in a direct expansion (DX) application, although the composition of the liquid changes during the boiling process, the composition of the vapour as it leaves the evaporator will be the same as the liquid composition that enters the evaporator, as shown in the following figure using R-407A as an example.

Temperature glide also occurs in the condenser and is just the opposite of the evaporation process although at much higher pressures and temperatures.

When sizing system components the mean evaporating temperature should be used. Using the bubble point or dew point will lead to under or oversizing of components.

Temperature glide should not cause any significant problems unless refrigerants with large temperature glides are used in applications where close control is needed (e.g. to control humidity in food storage) or in water chillers where there may be a risk of freezing in the evaporator. System design such as using counterflow heat exchangers can help to mitigate some of the effects of temperature glide and it is important to always use the dew point temperature when setting system superheats.