Getting the best out of A2L refrigerants in Commercial Refrigeration applications

Climalife UK

The ban on the use of R-404A and other >2500 GWP refrigerants for both new install and service in most commercial refrigeration applications has been in place for more than 18 months. This ban, together with price and availability issues brought about by the phasedown in CO2 equivalent quota, has placed more focus on what should be installed today to remain sustainable past 2030. Mid-range GWP blends such as Opteon™ XP40 (R-449A) are now well established for retrofit and can be used for new equipment in the interim but the GWP is just too high for the longer term.

The ban on the use of R-404A and other >2500 GWP refrigerants for both new install and service in most commercial refrigeration applications has been in place for more than 18 months. This ban, together with price and availability issues brought about by the phasedown in CO2 equivalent quota, has placed more focus on what should be installed today to remain sustainable past 2030. Mid-range GWP blends such as Opteon™ XP40 (R-449A) are now well established for retrofit and can be used for new equipment in the interim but the GWP is just too high for the longer term.

Mark Hughes MInstR - Business Development Manager EMEA, Chemours

Preparing for the future

The good news is that there is now plenty of equipment and components available on the market designed to use the very low GWP A2L refrigerants such as Opteon™ XL20 (R-454C) and XL40 (R-454A). The codes and standards are also becoming clearer, making it easier to understand what is needed for a new installation. Climalife, with the help of Chemours, can support you with this.

With the government pushing hard on targets for net zero greenhouse gas emissions by 2050, there is an increasing focus on the energy performance in many areas.

Choosing the right refrigerant

Once you reach very low GWP levels (below 300) it is the energy consumption of the system that is by far the major contributor to emissions and of course this also determines the cost of running the system during its lifetime.

Our previous articles showed the evidence that purpose designed refrigerants such as the A2L blends like Opteon™ XL20 (R-454C) from Chemours can give much better energy performance and life cycle costs (which also includes CAPEX and longer-term operating costs) than R-744. In many case studies the poorer performance of R-744 is compensated for by combining its use with heat recovery to improve the overall energy consumption . What is almost never mentioned is that A2L refrigerants can also have their efficiency boosted by employing such measures.

Studying the area of heat recovery

On the journey to net zero it is important to consider the most efficient way to provide not only cooling but also heating in a commercial application. As very little data has been published comparing approaches in this sector on a true “apples vs. apples” approach, WAVE, an independent engineering consultancy company, was engaged to look at the various ways this could be achieved and compare the solutions in terms of total emissions from the system. In addition, as heat recovery has often been seen in the past as a “nice to have” the costs of the various options were assessed to ensure emissions could be reduced at a reasonable cost. Systems that show good value in use are much more likely to be adopted, making the net zero target easier to achieve.

What the analysis shows

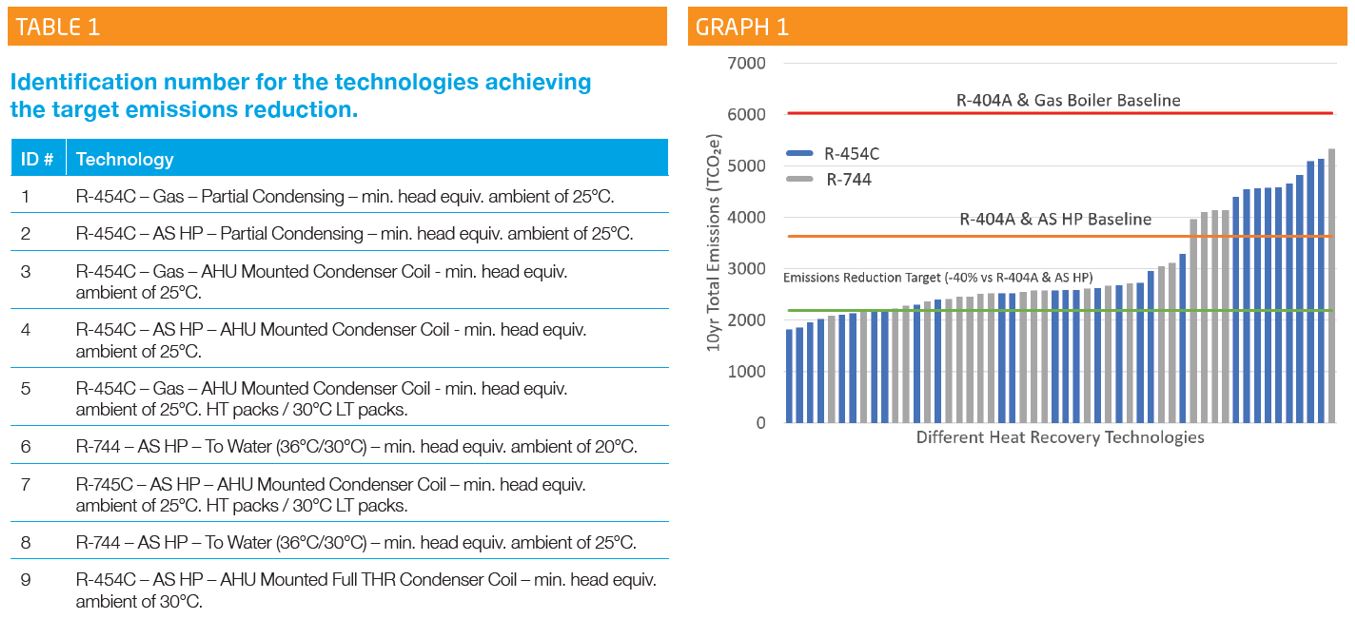

Typical heat recovery technologies were compared (Compressor discharge de-superheating, partial condensation and air handling unit mounted condensers/gas coolers) using low-GWP Opteon™ XL and R-744 refrigerants at various operating conditions in a moderate (Leicester, UK) climate shown in Table 1 below.

Emissions reduction targets were set at a nominal level (>64% reduction versus baseline) which selected the nine lowest emissions technologies (below the green line on Graph 1), of which seven were utilising Opteon™ XL refrigerants.

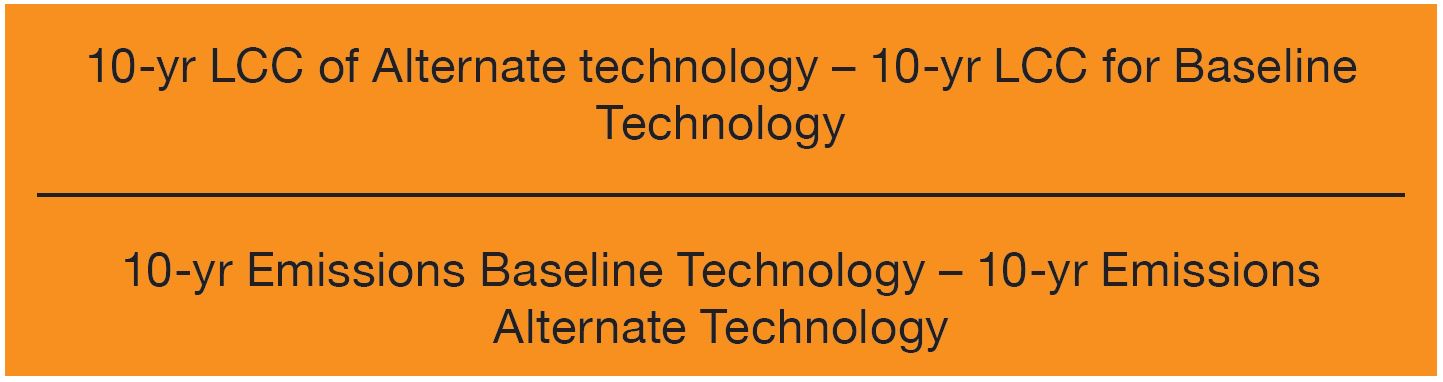

As the lowest emission technology does not always have the lowest cost, an analysis was done to evaluate which solutions provided emissions reductions at a reasonable cost. Calculation of the cost of abatement per Tonne of CO2 equivalent emissions (TCO2e) over a 10-year period is a method used to determine the most cost-efficient technology to reduce the environmental impact of a system. The relative emissions abatement cost can be calculated by using the following equation.

A negative abatement cost indicates the system 10-yr LCC is lower than the baseline R-404A technology. This calculation shows the technologies with the lowest abatement costs were using HFO based R-454C refrigerant.

Employing subcooling to enhance efficiency

In addition to the excellent performance of the Opteon™ XL products for both heating and cooling they are eminently suitable to squeeze out even better results by using some form of additional subcooling.

It is true that the addition of subcooling, as with employing heat recovery, does both increase the complexity and capital cost of systems but the very real saving in energy consumption with its effect on both emissions and life cycle cost, is well worth looking at as we move to the net zero target.

In readiness for this, Chemours has conducted extensive analysis into various subcooling technologies that could be employed in applications such as back of store cold rooms, retail area refrigeration and central distribution centres comparing Opteon™ XL20 R-454C with R-744 (CO2).

The analysis shows that even in moderate climates such as the UK there is scope for further energy saving and life cycle cost reduction especially when employing a non-boosted sub cooler layout. Such emissions reduction will become even more important in the future and the fact that systems can be designed to further reduce life cycle cost vs. a standard DX system is worth taking note of. Such savings are even greater when comparing the A2L solution versus R-744 architecture.

Conclusion

The results clearly show that the 10-yr total emissions from all Heat Recovery systems are significantly lower than the baseline R-404A with a gas boiler. In most cases, the 10-yr LCC is also considerably less. To drill down into these results, technologies using the low-GWP HFO based refrigerant R-454C delivered the lowest 10-yr total emissions at the lowest 10-yr LCC. At current power generation emissions rates, technologies utilising low-GWP HFO based refrigerants such as R-454C offer the lowest total emissions. In fact, nine different technologies (seven of which were using R-454C as the working fluid) saw at least a 40% reduction in emissions compared to a R-404A refrigeration and air source heat pump heating baseline.

This shows it is possible to harness HFO based A2L technology to provide both cooling and heating while reducing environmental impact without breaking the bank.

More details will be released with a white paper in September 2021 and you can get more information at bit.ly/opteonsubcooling

More info: Please contact Mark Hughes, Business Development Manager for Opteon™ Refrigerants at Chemours by email at mark.hughes@chemours.com if you wish to discuss or check out our website at opteon.com