A renewable bio-sourced alternative to traditional glycols.

Climalife UK

A renewable bio-sourced alternative to traditional glycols.

As professionals, and as part of our daily lives, we are all constantly looking to reduce emissions either directly, by using products with the lowest climate change potential or indirectly by reducing energy usage and using products with a low manufacturing carbon footprint.

In the refrigeration, air-conditioning and heat pump industry there are many great examples of low carbon footprint projects using energy efficient systems and very low GWP refrigerants, only to then use a non-renewable heat transfer fluid (HTF) such as monopropylene glycol (MPG) or monoethylene glycol (MEG). Both MEG and MPG are derived from fossil fuels, however there is an alternative which is plant based, manufactured from a renewable feedstock source, and does not require compromise.

Renewable low carbon source

The main purpose of any carbon mitigating technology should be to reduce the impact on the environment largely by offsetting non-renewable carbon with renewable carbon. With this in mind, the considerations of environmental impact begin way before the product is actually used and include the manufacturing process. In recent years the concept of embodied carbon has been introduced, which not only considers the environmental footprint of the final product in use, but also takes into account the carbon emissions involved with bringing the product to market.

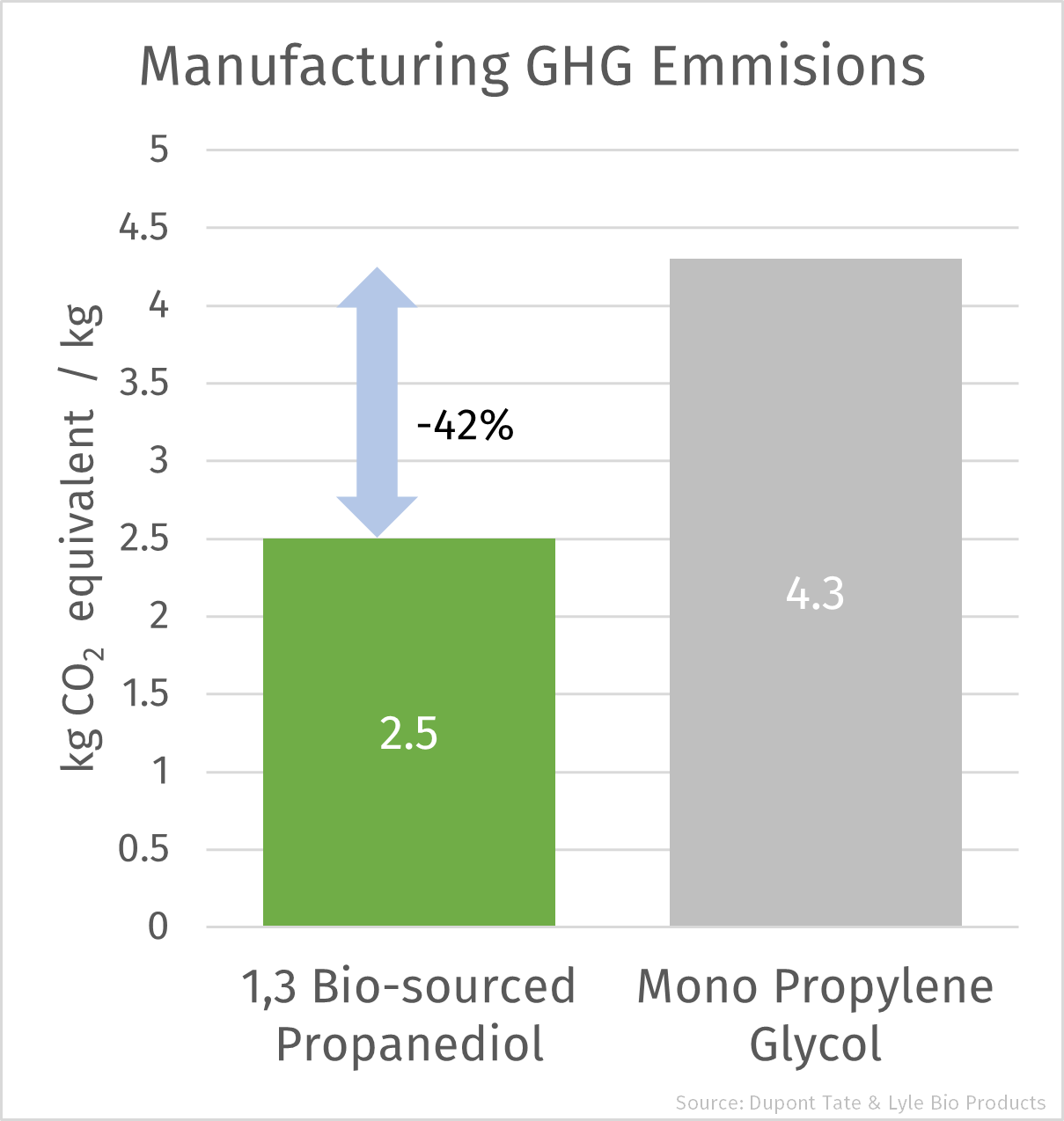

Bio-sourced HTFs such as Greenway® Neo N from Climalife have been shown to have a significantly lower embodied carbon, with >41% lower energy usage resulting in up to 42% lower emissions from raw material extraction to post-production delivery compared to the production of traditional MPG.

Bio-sourced HTFs such as Greenway® Neo N from Climalife have been shown to have a significantly lower embodied carbon, with >41% lower energy usage resulting in up to 42% lower emissions from raw material extraction to post-production delivery compared to the production of traditional MPG.

The base material for this bio-sourced HTF is manufactured via a fermentation and purification process from renewable dent corn, which is already grown on an industrial scale. The final product is 1,3‑propanediol, an isomer of the non-renewable 1,2-propanediol (MPG) traditionally used.

Long lasting effective corrosion inhibitors

As corrosion is likely occur without a suitable corrosion inhibitor package present, using pure glycol is not recommended. Many manufacturers of HTFs use traditional mineral-based inhibitor packages, but these can degrade over time and they also form a protective film on all metal surfaces, including heat exchangers, which can result in a reduction of the heat transfer rates lowering the system performance. An alternative to these mineral-based options, and the option used in HTFs produced by Climalife, are long life hybrid corrosion inhibitors also known as H-OAT (Hybrid Organic Acid Technology) which not only provide excellent long-lasting corrosion protection (ASTM D1384) but are also only deposited on the areas subject to corrosion avoiding the heat transfer blocking effect of the mineral-based inhibitors.

Biodegradable and bacteriostatic

Being plant based, HTFs based on 1,3-propanediol are biodegradable (90-100% in 28 days by the Zahn-Wellens/EMPA Test, OECD 302 B) leading to a reduced risk of soil pollution in the event of a leak and making them ideal for use in ground source heat pump systems.

Development of bacteria, mould, fungi, and algae are all possible and detrimental in secondary cooling circuits, but use of a product such as Greenway® Neo N which is bacteriostatic (ISO 11930) can prevent it from becoming an issue.

Energy and system cost savings

As might be expected the properties of 1,3-propanediol are similar to the traditional 1,2‑propanediol but there are some differences which lead to potentially significant additional operational benefits.

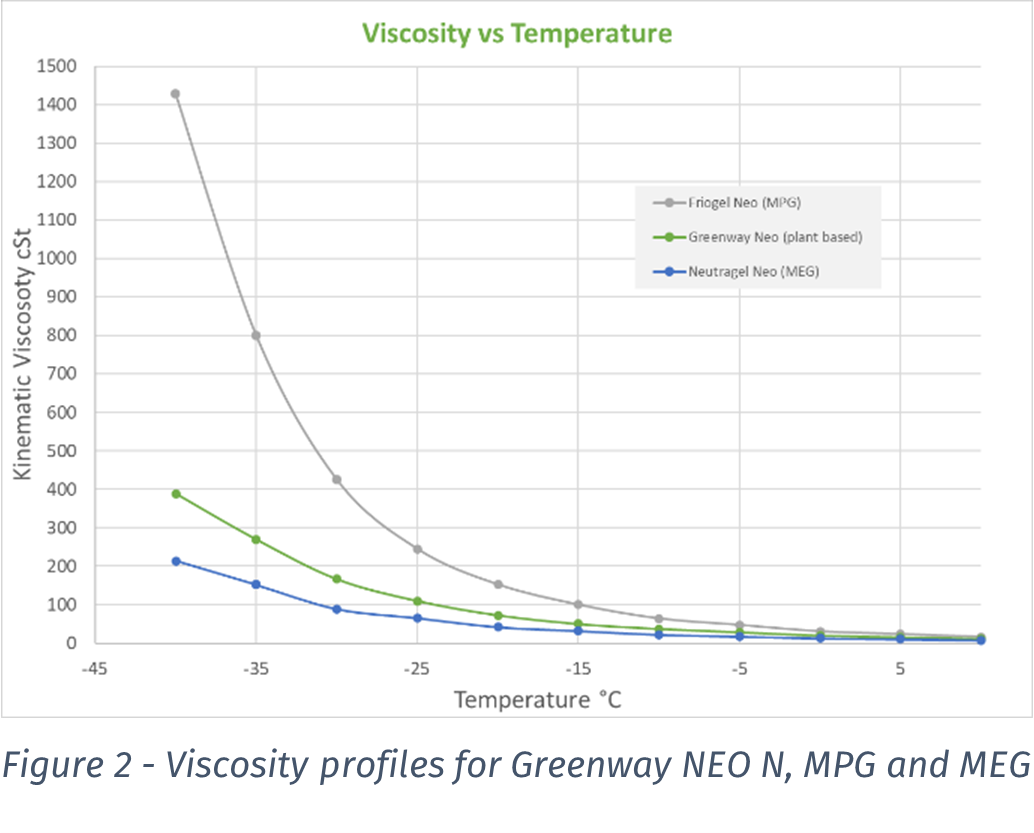

The viscosity of the plant based HTF, such as Greenway® Neo N, is significantly lower (>40% below -10°C) than traditional MPG. This lower viscosity even allows use down to very low temperatures (-55°C).

Testing published by Climalife has shown that power consumption at various conditions and flow rates is between 3% to 12% lower for the plant based HTF compared to equivalent traditional MPG solutions. As well as seeing energy savings from pumps, the lower pressure drops can also lead to lower costs due to smaller pump and pipe diameter requirements and can even lead to a reduction in the operating noise level of the pumps.

Food Applications

Often the phrase ‘food safe’ is used when choosing a HTF in applications where there is the risk of accidental contact with food.

Traditional MPG is often referred to as ‘food safe, but strictly speaking ‘food safe’ does not exist as any item which is not included on the intended ingredients list, even water if not listed, would be considered a contaminant, and not be allowed to enter the food chain.

However, there is a certification issued by NSF (National Sanitation Foundation) that recognises products that are food grade and safe for incidental contact with food. Greenway® Neo N has met the requirements to be registered NSF (National Sanitation Foundation) HT1 across a wide temperature range and is fully NSF and FDA compliant for use in a food processing/handling environment.

High Temperature Applications

Most MPG and MEG based HTF products have an upper limit of around 150°C for the recommended operating range. Products based on the plant based 1,3-propanediol have an improved thermal stability and can have a recommended upper limit of up to 200°C, making it ideal for high temperature heat pump applications and solar thermal applications where very high temperatures are often encountered.

The longevity of bio-sourced HTFs was demonstrated in a case study published by Climalife which featured an air source heat pump application installed in 2017. The HTF had never been changed, and samples taken from the system were analysed after 6 years of operation. The results showed that no significant degradation of the fluid had occurred and there were no signs of any system corrosion within the sample.

Offer the full package

The humble heat transfer fluid has often been overlooked when it comes to offering a fully sustainable and low carbon solution. Maybe because of habit, maybe because it’s not seen as the most critical component, but surely, if there is a renewable and sustainable option that potentially offers performance benefits as well. At least worth considering, isn’t it?